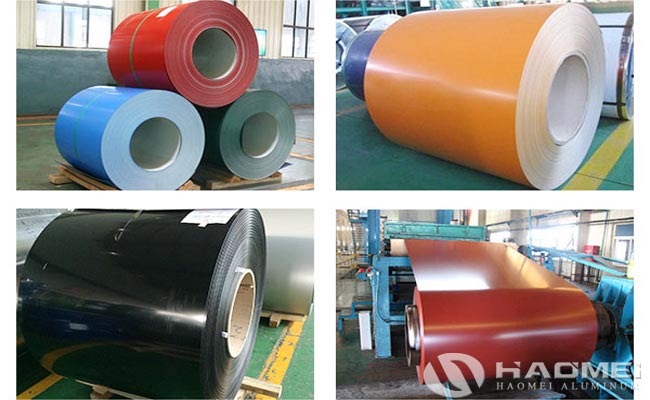

In recent years, colored aluminum sheets have received more demand in the industrial industry. Whether it is used as a material for door and window or decorative handicrafts, it is very competent, and aluminum metal also accounts for a large amount of reserves compared to other metals. Therefore, the construction industry, the electronics industry and lighting products are all in demand for color coated aluminum sheet coil.

Roll coating is the common seen painting method of color coated aluminum sheet, this coating method has the advantages of:

1. High output.

Roll production is automated, with a slow speed of 20 meters per minute, and high speed of 60 meters per minute, and can reach the speed of over 100 meters per minute. Calculated by aluminum sheet with thickness of 0.8mm, the output is 100 meters per minute, the output is 260 kilograms, and 125 tons of coated aluminum sheet can be produced in 8 hours.

2. Save paint and energy.

The paint used in the process of painting the aluminum plate is recycled, with little waste. One kilogram of paint can be coated with more than 10 m2 aluminum sheet. Compared the spraying line, one kilogram of paint can only be coated with 4 square meter aluminum sheets, and most of the paint are wasted in the sink. The oven for the roll line is compact and saves a lot of heating energy compared to the spaying line oven.

3, the roller coated aluminum sheet paint surface is more delicate.

In some delicate decorative panels, the paint surface of the colored aluminum sheet is required to be fine, and the roll coating is one of the better processes. The spray plate is prone to the phenomenon of orange peel on the surface.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form