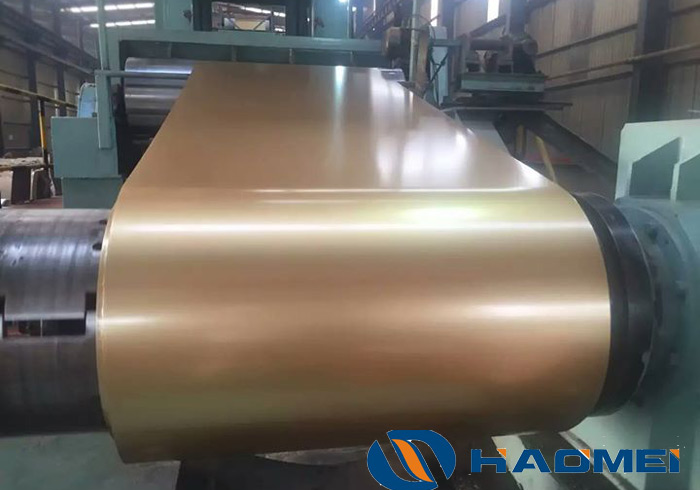

Due to the color coated aluminum sheet has advantages of both the aluminum sheet itself and the surface coating material, it has high mechanical strength, toughness, easy to processing, and other outstanding performance as rich colors, decorative, corrosion-resistant, easy for punching, bending, deep drawing, welding and other processing. Haomei Aluminum engaged in the production development and technology of color coated aluminum sheet for many years, here is the brief introduction about how does color coated aluminum is produced.

Color coated aluminum processing generally has two steps: the substrate processing and the surface material coating.

First, the substrate processing

In order to painting more smoothly, deal with the substrate is needed before painting. As the surface of the aluminum sheet will remain some grease and lubricants in the production process, and during transport the surface may also attach some other substances, these should be cleaned before processing, or the processing problems will affect the quality.

Second, the surface coating

General color coated aluminum sheet coating process can be divided into three type by the coating layer, three coating process, two coating process and single coating process. By coating roller and drive roller rotation direction can be divided into along coating and reverse coating. If the coating roller rotation direction and the substrate are in the same direction, the coating method is along coating. On the contrary is reverse coating. Coating process generally only painted lower wet film thickness, and the film surface appearance is not ideal, so this type is not often used. Reverse coating process is currently the most used coating process, by adjusting the rotation ratio between the roller and the substrate travel speed, we can get the desired thickness, the smooth surface appearance coating.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form