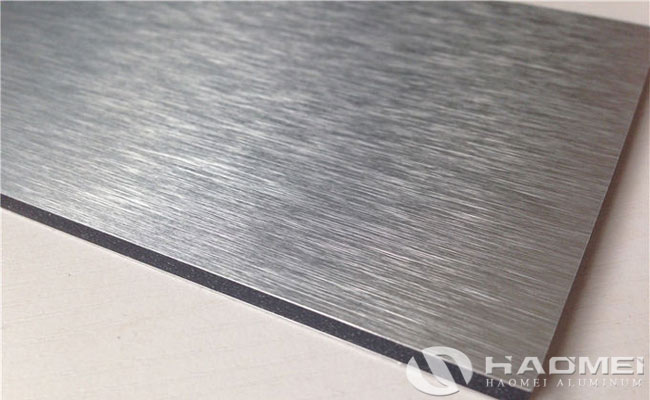

The brushed aluminum sheets can make the product to achieve the beautiful appearance, and has the characteristics of bright, uniform and fashionable surface, giving a strong visual impact. Brushed aluminium sheets are well used in both production processing and in electronic components. So, what is the brushing method for the surface of the brushed aluminium sheet?

The surface brushing method of the brushed aluminum sheets has two ways of hand drawing and mechanical drawing. Common hand-drawing is mostly used in industrial scouring pads, such as 8698, 7447C, etc. The most used method is the mechanical drawing method. There are several common ways of mechanical drawing:

1, non-woven roller brush drawing

The aluminum sheet is conveyed by a conveyor belt through a non-woven roller brush, and the roller brush is drawn at a high speed to draw the surface of the aluminum sheet. The roller brush vibration and the roller brush non-vibration can be used when drawing, and at the same time, different processing speeds can be used to produce different length lines. The non-woven roller brush vibrates to produce a very uniform and consistent discontinuous thread (short yarn); the non-woven roller brush does not vibrate and can produce continuous filaments (filaments or straight filaments).

2, flat pressure belt drawing

Flat-press drawing is a common drawing method. The aluminum sheet is fixed on the mold. The abrasive belt runs at high speed. The back of the belt has a pneumatically controlled pressure block that can move up and down. After pressing, the belt is attached. The machined surface is drawn. The commonly used equipment is a flat belt machine.

The above is about the drawing method of the brushed aluminium sheets surface. For the wire drawing processing method of aluminum alloy material, there are certain requirements for the wire drawing effect, and the shape and size of different surfaces are also different, so the processing methods are also different.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form