7075 t6 aluminum sheet has become an well known aviation aluminum plate due to its high ultra-high hardness and ultra-high hardness. 7075 aluminum plate is widely used in aerospace, mold processing, auto parts, electronic appliances, automation and other fields. 7075 aluminum plate can be divided into 7075 thin aluminum plate, 7075 medium thick aluminum plate and 7075 ultra thick aluminum plate.

Among them, the thin 7075 aluminum sheet state is 7075-T6 aluminum sheet and 7075-TO aluminum sheet, which is mainly used in automotive parts, aviation parts, electronic product casings and other high-strength mechanical parts. Aluminum sheet 7075 TO has good ductility and can be used in bending, stamping and other processing fields. At the same time, our company can also provide customers with aluminum sheet annealing, aluminum sheet quenching, aluminum sheet hardening and other processing.

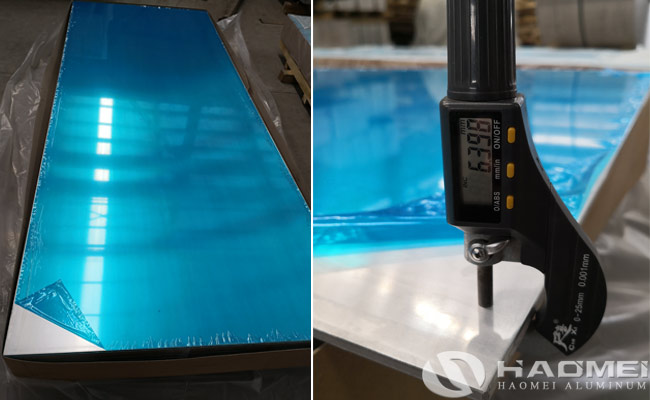

The 7075 medium-thick aluminum plate is divided into 7075-T6 and 7075-T651 aluminum plates. The 7075-T6 aluminum sheet plate is a quenched aluminum plate, it has no pre-stretching treatment, the internal stress distribution is uneven, and the processing is easy to deform, it is only suitable for small-size parts processing. 7075-T651 aluminum plate belongs to pre-stretched aluminum plate, which have high hardness, no deformation, good flatness and stable anodizing effect.

7075 ultra-thick aluminum plate temper is 7075-T652, 7075-T652 aluminum plate thickness is generally greater than 200mm, most of which are used to make various molds or large-scale accessories. The 7075 aluminum plate in this state has a denser material, higher hardness and higher strength. The characteristics of processing are not deformed.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form