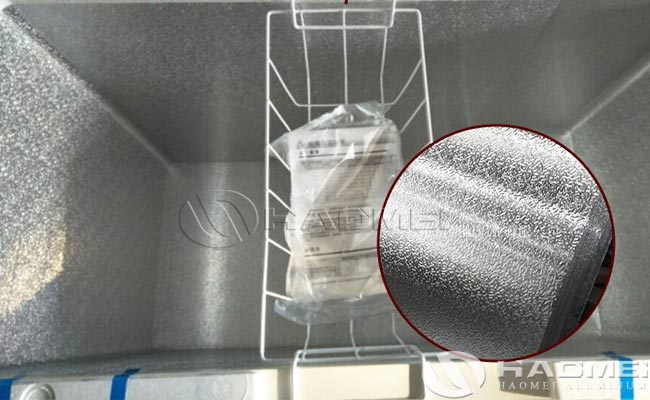

Stucco embossed aluminum coil for freezer liner panel typically offer excellent corrosion resistance, lightweight, low-temperature resistance, easy cleaning and superior insulation properties. The stucco embossed aluminum coils undergo a special surface treatment to effectively prevent frost and moisture accumulation, while also providing aesthetic appeal.

- Material Characteristics and Application Scenarios

– Alloy Selection

3003 Aluminum alloy: An aluminum-manganese alloy (containing 1.0-1.5% manganese) with excellent rust resistance, suitable for high-humidity environments, is widely used in cold storage and freezer liners.

1060 Pure Aluminum: With a purity of ≥99.6%, a thermal conductivity of 237 W/m·K, and fast cooling, it is commonly used in refrigerator evaporators.

– Surface Treatment:

Anodizing (thickness ≥15μm) creates a dense Al₂O₃ layer that withstands salt spray testing for ≥500 hours.

Color coated with PE/PVDF coating.

– Embossing Process

Orange Peel Texture: The surface features a honeycomb-like pattern, increasing contact area and improving thermal conductivity (15-20% higher than flat panels) while also enhancing panel rigidity (thickness increases by 0.1-0.25mm).

– Specifications

Thickness: 0.8-2.0mm (balancing strength and lightweight), Width: 1000-1600mm (compatible with conventional freezer dimensions).

Tolerance: ≤0.01mm difference between panels, ≤1mm width tolerance, ensuring seamless splicing.

Key performance verification of stucco embossed aluminum coil:

– Low-Temperature Resistance Test

-40°C Impact Test: 3003-H14 aluminum alloy demonstrates a tensile strength of ≥145MPa and an elongation of ≥8% at -40°C, with no brittle cracking.

Thermal Cycle Test: After 1000 cycles from -25°C to room temperature, the oxide film achieved Grade 1 adhesion (cross-hatch method) with no peeling or flaking.

– Health and Safety

Food-Grade Certification: Certified under FDA 21 CFR 175.300 (US) and EU (EC) No. 1935/2004, with aluminum migration ≤ 5mg/kg, meeting domestic food contact requirements according to GB 4806.9-2016.

Antimicrobial Treatment: Optional silver ion coating (Ag⁺ release 0.01-0.1ppm) inhibits the growth of Escherichia coli and Staphylococcus aureus (inhibition rate >99%).

Our production base provides 0.8-8.0mm orange peel aluminum sheet, with 3003 aluminum alloy comprising over 60%. We support surface treatments such as anodizing and color coating, and provide SGS testing reports. With an annual production capacity of 200,000 tons, we supply home appliance companies such as Haier and Midea.

– Typical product

Model: 3003-H14 stucco embossed aluminum coil

Specifications: Thickness 1.2mm x Width 1220mm, Compliant with GB/T 3880.2-2012

Performance: Salt spray test >1000 hours, Thermal conductivity 205W/m·K, Surface roughness Ra 1.6-3.2μm

– Price Range

Regular product: 3003 orange peel aluminum coil, approximately 3,100-3,500 dollars/ton.

Customization: Anodizing adds 200-300 dollars/ton, and antibacterial coating adds another 100-200 dollars/ton.

– Technology Upgrades

Nano-coatings, such as PVDF fluorocarbon coating, offer improved weather resistance up to 20 years, making them suitable for highly corrosive seafood cold storage.

Composite structure: Aluminum sheet + polyurethane foam layer (thermal conductivity ≤ 0.024 W/m・K), achieving integrated insulation and protection.

Stucco embossed aluminum coil, as a material for freezer liner panels, is a key choice in refrigeration equipment manufacturing due to its excellent performance and adaptability, making it suitable for use in low-temperature and high-humidity environments. Choosing the right embossed aluminum material can effectively improve the performance and lifespan of your freezer.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form