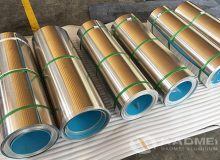

Aluminum Jacket with Polysurlyn Moisture Barrier

Aluminum roll jacketing with polysurlyn moister barrier is recommended for insulated piping, tanks and vessels. The aluminum roll laminated with polysurlyn composite materials with high strength and corrosion resistance already replaces the polykraft moisture retarders. The aluminum with polysurlyn composite material’s service life can reach 7 years without any maintenance, it has excellent resistance to corrosion.

POLYSURLYN MOISTURE RETARED

Polysurlyn consists of 50-200um thickness of a polyethylene or a DuPont’s Surlyn which is heat and pressure bonded to the interior surface, provides a highly effective moisture retarder. Polysurlyn Moisture Barrier is heat laminated in the factory to the interior surface of all types of metal jacketing for mechanical insulation to help prevent pitting, crevice, and galvanic decomposition of the interior apparent of the metal jacketing and the underlying insulated pipe, tank, or equipment. This corrosion can occur when water enters the installed insulation system through joints or damage in the metal jacketing.

Polysurlyn is manufactured from 3 layers of film: 1 mil high-density polyethylene, 1 mil Surlyn, and 1 mil low-density polyethylene, with each layer carefully selected to yieldoptimum performance. This multilayer film is laminated to the interior side of aluminium and stainless steel jacketing using precise pressure and heat. Use of 3 mil thick three layer Polysurlyn Moisture Barrier (PSMB) film avoids the pinholes prevent in standard 1 mil single layer Polykraft Moisture Barrier(PKMB). When water is present and touching the metal jacket, corrosion can and does occur. This can happen in all applications (hot, cold, rooftop, industrial, commericial, etc.) and with all insulation types.

Polysurlyn moisture barrier has advantages:

1, Simple, low cost, and effective resistance to metal jacket and pipe corrosion;

2, Provides a barrier to crevice or pitting corrosion on the inner jacket surface in cold and hot pipe/tank applications;

3, Provides a barrier to galvanic corrosion of jacket or pipe in hot applications;

4, Minimal water absorption compared to kraft paper;

5, Will not deteriorate, discolor or shred when exposed to water;

6, Provides abrasion resistance during installation;

7, Long term durability and resistance to a wide range of environmental contaminants.

Specification of aluminium jacket with PSMB:

Alloy: 1050, 1060, 1100, 1200, 3003, 3015, 5005

Temper: H14, H16, H24, H26,

Thickness: 0.4mm-1.5mm

Standard width: 914mm 1000mm 1200mm 1219mm

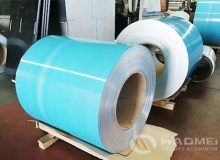

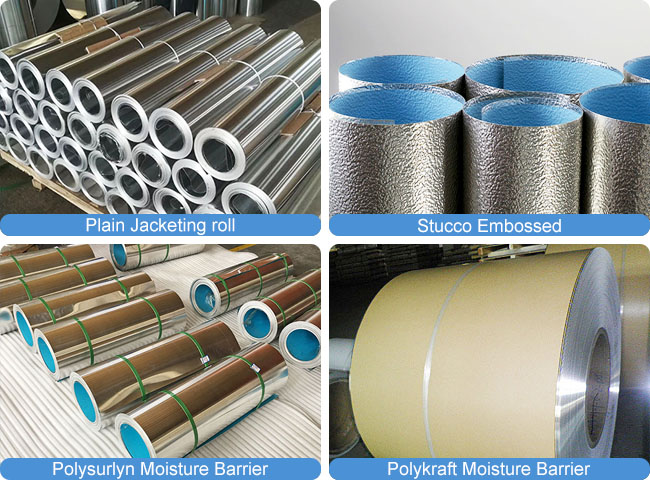

Surface:Plain, Flat, Mill finish, Smooth, Stucco embossed

Coatings: PE/PVDF Coated, PolySurlyn Polykraft paper Laminated

Kraft paper thickness: about 0.1mm

Polysurlyn thickness: about 0.076mm (3mil)

Inner diameter: 305mm, 405mm or 505mm with paper core or without core

Out diameter: 125m, 150m, 250m ,300m, 500m, 1000m, 2540m or according to coil weight

Quality standard: ASTM B209 EN573-1

Quantity: have ready stock, small quantity order are acceptable.

Application: Industrial insulation jacketing, cover, insulation protective jacketing

Features of aluminum with polysurlyn moisture barrier are:

1.Customized packaging solutions for extended shelf life

2.Excellent barrier against moisture, oxygen & odour

3.Excellent mechanical properties even at low thickness

4.High burst strength and puncture resistant.

Application of aluminum jacket with polysurlyn:

1, Standard outdoor use on all pipe, vertical tank insulation systems up to 8 ft outer diameter, and all horizontal tanks.

2, Indoor insulation system applications up to 8 ft outer diameter where increased damage resistance is desired.

| Alloy | Temper | Thickness(inch) | Thickness(mm) | Width(mm) | Length(m) | Suggested Application |

| 1100, 1060, 3003, 3105, 5005 | H14, H16, H24, H26 | 0.012 | 0.3 | 914, 1000, 1219 | 20, 25,30, 60, 90, coil | OD below 36″(914mm) insulated pipe lines. |

| 0.016 | 0.4 | 914, 1000, 1219 | 20, 25,30, 60, 90, coil | OD below 36″(914mm) insulated pipe lines. | ||

| 0.020 | 0.5 | 914, 1000, 1219 | 20, 25,30, 60, 90, coil | OD below 36″(914mm) insulated pipe lines. | ||

| 0.024 | 0.6 | 914, 1000, 1219 | 20, 25,30, 60, 90, coil | OD 36″-8′ (914mm-2.43m) insulated pipe lines&equipment. | ||

| 0.032 | 0.8 | 914, 1000, 1219 | 20, 25,30, 60, 90, coil | Special applications where extra thickness and protection is required, such as fabricated tank head covers and other special fabrications. | ||

| 0.040 | 1.0 | 914, 1000, 1219 | 20, 25, 30, 60, 90, coil | Special applications where heavy mechanical is required. | ||

| 0.050 | 1.2 | 914, 1000, 1219 | 20, 25, 30, 60, 90, coil | Flat ducts or precipitators. Also recommended for areas subject to high wind conditions. |

| Alloy | Si | Fe | Cu | Mn | Zn | Mg | Ti | Cr | Other Elements | Al | |

| Each | Total | ||||||||||

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.05 | 0.03 | 0.03 | – | 0.03 | 99.6min | |

| 1100 | Si+Fe=0.95 | 0.05-0.20 | 0.05 | 0.10 | – | – | – | 0.05 | 0.15 | 99.0min | |

| 3003 | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.50 | 0.10 | – | – | – | 0.05 | 0.15 | reminder |

| 3105 | 0.6 | 0.7 | 0.30 | 0.30-0.80 | 0.40 | 0.20-0.80 | 0.10 | 0.20 | 0.05 | 0.15 | reminder |

| 5005 | 0.3 | 0.7 | 0.20 | 0.20 | 0.25 | 0.50-1.10 | – | – | 0.05 | 0.15 | reminder |

- Verified supplier:

We are verified supplier, with quality assurance. Production process is approved by SGS and BV.

- Price Competitive:

We provide factory price to save your purchase cost.

- Customized size:

We can produce any size according to clients requirement. We further provide clients with aluminium sheet/coil further process, such as anodizing, brush, polish, stucco emboss, corrugation, mirror, color coating etc.

- Safe package and Fast delivery:

About 25-40 days after receipt client LC or deposit.

- Existing clients reference:

Our aluminium products are exported to all over the world, we can give you our existing customer name in your region for you to check our company and our quality.

- Free samples:

Haomei supply free sample available for test at first.

- After sales service:

We have good reputation for all customer; If any quality problem with third party inspection report, We will take full responsibility.

Related Products

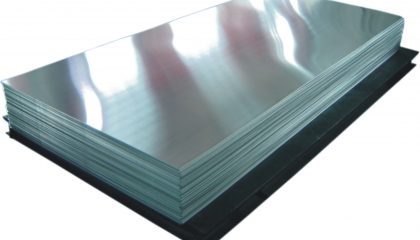

1060 Aluminum plate sheet

1060 Aluminum plate sheet with aluminum content of up to 99.6%, also known as pure aluminum plate, 1060 aluminum plate sheet has a good elongation and tensile strength, fully able to meet the requirements of conventional processing (stamping, stretching) high formability (1060).

Stucco embossed aluminum with kraft paper

Alloy no.:3003, 3004, 3105(antirust), 1050, 1060, 1100(normal) Temper : H14 ,H16 ,H24 ,H26 Thickness: 0.2-2.0mm Width: 914 mm, 1000, 1200, 1220mm or as customer's requirement Length: 2000-30000mm

Aluminum Jacketing For Ductwork

Haomei supply commonly used aluminum jacketing for ductwork alloy grades 1060 aluminum, 1100 aluminum, 3003 aluminum, 5005 aluminum, etc.

Aluminum Jacket with Polykraft Moisture Barrier

Haomei aluminum jacket with polykraft moisture barrier are applied pipe insulation, build facade, protection for insulated equipment etc.

Aluminum Jacket with Polysurlyn Moisture Barrier

Aluminum roll jacketing with polysurlyn moister barrier 1060 and 3003 is recommended for insulated piping, tanks and vessels.

3003 aluminum sheet

3003 aluminum sheet plate is typical aluminum alloy Al-Mn,has good formability, corrosion resistance and weldability,commonly used inautomotive lightweight, storage tank, cooking utensils, food warehouse transport equipment, sheet metal pressure vessels and piping.Haomei Aluminum Sheet Plate

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form