Aluminum Jacket with Polykraft Moisture Barrier

Aluminum Jacketing with polykraft moisture barrier is manufactured from wrought aluminum alloy 1060, 3003 or 5005 according to ASTM B209 with H14 and H16 temper. The properties of these aluminum alloys provide the required strength to resist in-service abuse, but can be easily fabricated and installed. PKMB – POLYKRAFT MOISTURE BARRIER makes aluminum jacketing suitable for most general industrial applications. It will keep your insulation dry and functional. Polykraft laminated aluminum coil for insulation jacketing & cladding and many other application, coil is available as per customized requirement.

Aluminum +Polykraft

Polykraft consists of one layer of one mil polyethylene film with a protective layer of 80g/m2 virgin kraft paper.

The moisture barrier is factory applied by attaching the jacketing by continuous lamination to the full width of the metal, low emissivity value of aluminium reduces heat loss.

The moisture barrier is used to prevent moisture and corrosives in the insulation from coming into direct contact with the metal jacketing surface and causing galvanic or chemical corrosion.

Polycraft is a layer of kraft paper laminated to a thin layer of polyethylene film which is factory applied on the metal in a lamination process. It is an improvement from the paint system as Polykraft is 1.5 mil (37.5μm) thick and uses polyethylene layer which is good for moisture resistance.

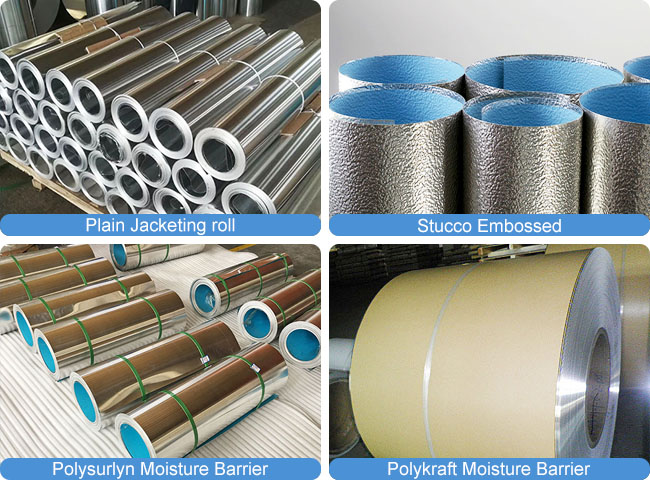

The classification of aluminium jacketing with polykraft:

Stucco Embossed Finish

The Stucco like surface texture hides small scratches and imperfections, caused by physical damage during or after installation. This finish also reduces reflectivity while still looking very professional. The use of stucco embossed aluminum with polykraft moisture barrier provides a small increase to the rigidity and strength of the aluminum jacketing.

Smooth (Plain Mill) Finish

The Plain Finish is very popular for the many end-users who prefer the clean look of this finish. This finish sheds rain water the best. This smooth surface readily shows damage such as from hail or any physical abuse. It also shows the dust/dirt more than the other finishes due to its smoothness. The plain aluminum with polykraft moisture barrier finish is highly reflective of sunlight specially when located near roadways.

The specification of aluminum jacket with polykraft paper:

| Alloy | Temper | Thickness(inch) | Thickness(mm) | Width(mm) | Length(m) | Suggested Application |

| 1100, 1060, 3003, 3105, 5005 | H14, H16,H24, H26 | 0.012 | 0.3 | 914, 1000, 1219 | 20, 25,30, 60, 90, coil | OD below 36″(914mm) insulated pipe lines. |

| 0.016 | 0.4 | 914, 1000, 1219 | 20, 25,30, 60, 90, coil | OD below 36″(914mm) insulated pipe lines. | ||

| 0.020 | 0.5 | 914, 1000, 1219 | 20, 25,30, 60, 90, coil | OD below 36″(914mm) insulated pipe lines. | ||

| 0.024 | 0.6 | 914, 1000, 1219 | 20, 25,30, 60, 90, coil | OD 36″-8′ (914mm-2.43m) insulated pipe lines&equipment. | ||

| 0.032 | 0.8 | 914, 1000, 1219 | 20, 25,30, 60, 90, coil | Special applications where extra thickness and protection is required, such as fabricated tank head covers and other special fabrications. | ||

| 0.040 | 1.0 | 914, 1000, 1219 | 20, 25, 30, 60, 90, coil | Special applications where heavy mechanical is required. | ||

| 0.050 | 1.2 | 914, 1000, 1219 | 20, 25, 30, 60, 90, coil | Flat ducts or precipitators. Also recommended for areas subject to high wind conditions. |

Features of aluminum jacketing with polykraft paper are:

1.Customized packaging solutions for extended shelf life

2.Excellent barrier against moisture, oxygen & odour

3.Excellent mechanical properties even at low thickness

4.High burst strength and puncture resistant.

| Alloy | Si | Fe | Cu | Mn | Zn | Mg | Ti | Cr | Other Elements | Al | |

| Each | Total | ||||||||||

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.05 | 0.03 | 0.03 | – | 0.03 | 99.6min | |

| 1100 | Si+Fe=0.95 | 0.05-0.20 | 0.05 | 0.10 | – | – | – | 0.05 | 0.15 | 99.0min | |

| 3003 | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.50 | 0.10 | – | – | – | 0.05 | 0.15 | reminder |

| 3105 | 0.6 | 0.7 | 0.30 | 0.30-0.80 | 0.40 | 0.20-0.80 | 0.10 | 0.20 | 0.05 | 0.15 | reminder |

| 5005 | 0.3 | 0.7 | 0.20 | 0.20 | 0.25 | 0.50-1.10 | – | – | 0.05 | 0.15 | reminder |

1. Verified supplier:We are verified supplier, with quality assurance. Production process is approved by SGSand BV.

2. Price Competitive: We provide factory price to save your purchase cost.

3.Customized size:We can produce any size according to clients requirement.We further provide clients with aluminium sheet/coil further process, such as anodizing, brush, polish, stucco emboss, corrugation, mirror, color coating etc.

4. Safe package and Fast delivery: About 25-40days after receipt client LCor deposit.

5. Existing clients reference: Our aluminium products are exported to all over the world,we can give you our existing customer name in your region for you to check our company and our quality.

6. Free samples: Haomei supply free sample available for test at first.

7. After sales service:We have good reputation for all customer; If any quality problem with third party inspection report, We will take full responsibility.

Aluminum Jacketing is recommended for use in all of the following insulation system applications:

- Standard outdoor use on all pipe, vertical tank insulation systems up to 8 ft outer diameter, and all horizontal tanks.

- Indoor insulation system applications up to 8 ft outer diameter where increased damage resistance is desired.

Related Products

Aluminum Jacketing For Ductwork

Haomei supply commonly used aluminum jacketing for ductwork alloy grades 1060 aluminum, 1100 aluminum, 3003 aluminum, 5005 aluminum, etc.Haomei Aluminum Sheet Plate

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form