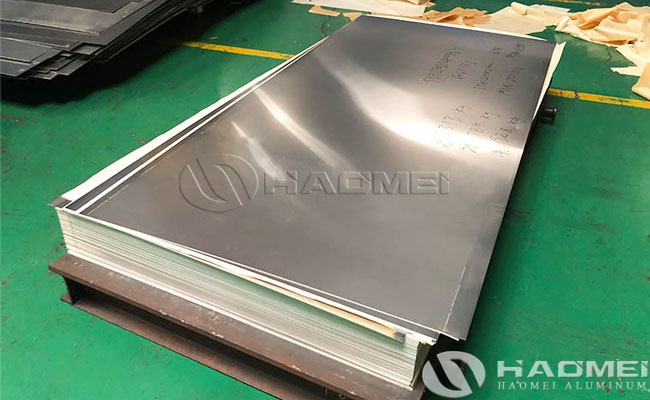

Haomei Aluminum, a company with many years of experience in aluminum sheet manufacturing and export, understands that mill-finished plain aluminium sheets are a fundamental core material in the industrial field. These aluminum sheets refer to products that, after rolling and extrusion forming, do not undergo secondary surface treatments such as anodizing or spraying, retaining their original rolled state. Their pure material properties and flexible adaptability make them a preferred basic material for global B2B customers.

The accuracy of specifications directly determines application adaptability. We strictly adhere to international standards such as ASTM, EN, and GB/T in our production. Alloy systems of our mill-finished plain aluminium sheets cover 1000 series (1050, 1060, 1100) pure aluminum, 3000 series (3003) aluminum-manganese alloys, and 5000 series (5052) aluminum-magnesium alloys, meeting different strength and corrosion resistance requirements. Thickness range 0.15-300mm, maximum width up to 2200mm, length cut to 8000mm as needed, tolerance controlled within ±0.01mm. Available in O state (soft), H14/H24 (semi-hard), and H112 (naturally aged), suitable for various processing scenarios such as bending, stamping, and welding.

The stability of the original surface quality is the core competitiveness of mill-finish plain aluminum sheets. We ensure quality through triple control:

High-precision rollers are used in the rolling process, with strict control of rolling temperature and speed to avoid defects such as orange peel effect and roll marks.

Finished products undergo visual inspection and eddy current non-destructive testing to ensure no cracks, inclusions, oxide film inclusions, etc., with uniform surface color and only slight rolling texture (a normal original characteristic). Packaging uses blue PE protective film and export standard wooden pallets to prevent scratches and corrosion during transportation.

Minor surface imperfections can be treated with post-processing grinding and do not affect mechanical properties.

Cost and adaptability are its core advantages. Eliminating the need for secondary surface treatment not only reduces production costs but also shortens delivery cycles, making it particularly suitable for bulk purchasing needs. The original surface retains the inherent properties of aluminum, offering superior electrical and thermal conductivity and formability compared to treated aluminum sheets, and providing a good substrate for subsequent spraying and anodizing. The naturally formed oxide film possesses basic corrosion resistance, and combined with optimized alloy composition, it is suitable for most neutral environments. Haomei Aluminum optimizes the rolling process, ensuring product flatness deviations are below industry standards, reducing processing losses for customers.

Thanks to its diverse properties, mill-finished plain aluminium sheets’ applications span multiple sectors globally:

In the construction industry, it is used for ventilation ducts and ceiling substrates.

In the transportation industry, it is suitable for truck bodies and cargo bed liners.

In the home appliance industry, it is used as a refrigerator panel and radiator substrate.

It can also be used in packaging containers, electronic device brackets, and general sheet metal parts.

For customers in maritime climate regions, we recommend the 3003 and 5052 alloy series, which, through composition adjustments, enhance salt spray corrosion resistance, and we have already provided customized solutions for customers in Southeast Asia and Europe.

With its stringent production control and global service experience, Haomei Aluminum provides customers with highly consistent mill-finished plain aluminum sheets, balancing cost-effectiveness and processing flexibility to help upgrade end products across various industries.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form