The surface treatment of colorful coated aluminum coil mainly includes spraying, rolling and laminating. With the development of science and technology, new surface treatment processes od color coated aluminum coil continue to emerge.

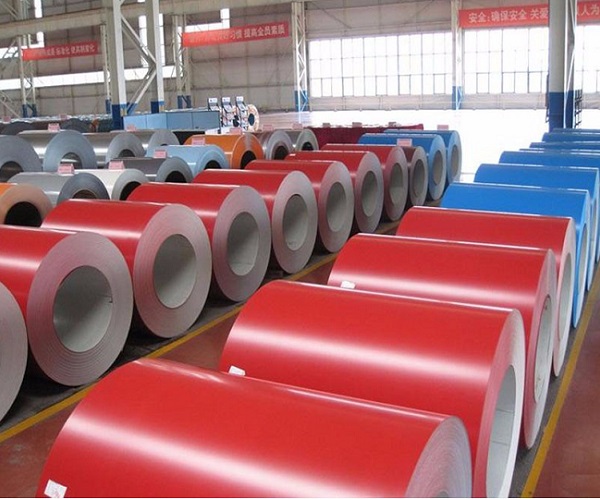

colorful coated aluminum coil

Spraying: It is made by spraying colorful paint on the surface of aluminum coil and then drying it. The color distribution of a good spraying aluminum coil is even, and the color of a poor coated aluminum coil is corrugated when viewed from the side. The spray paint is mostly matte, and the folds are available at right angles and oblique angles. The color coated aluminum sheet must be dried so that the paint film is firm. The painted aluminum sheet coil for ceiling has the same color on the front and back, while the front and back of the painted aluminum sheet are different.

Roll coating: After degreasing and chemical treatment on the surface of the aluminum coil, high-quality paint is rolled and dried and cured. The smoothness of the paint film on the surface of the roll-painted colorful coated aluminum coil is higher than that of the spray-coated aluminum coil. The color is divided into pearlescent and matte, and most of the common ones on the market are pearlescent.

Laminating: It is made of color coated aluminum sheet as the base material, using high-gloss film or phantom color film, and the surface of the plate is coated with a professional adhesive and then compounded. The laminated board has bright luster, a wide variety of colors to choose from. The colorful coated aluminum coil with lamination film is waterproof and fireproof, has excellent durability (weather resistance, corrosion resistance, chemical resistance), anti-fouling ability, and superior UV resistance. The membrane is divided into imported membrane and domestic membrane LG membrane. The durability and gloss of imported membrane is better than domestic membrane! The high-quality aluminum gussets on the market mostly use South Korean LG film, and the thickness of the aluminum gussets should be about 0.6mm.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form