Color anodized aluminum sheet is treated with an anodizing process to create a colored oxide film on its surface. The aluminum sheet acts as the anode and is placed in an electrolyte (such as sulfuric acid or oxalic acid). Direct current is applied to the surface, forming a dense aluminum oxide (Al₂O₃) film. This film has a porous structure, providing a foundation for subsequent coloring.

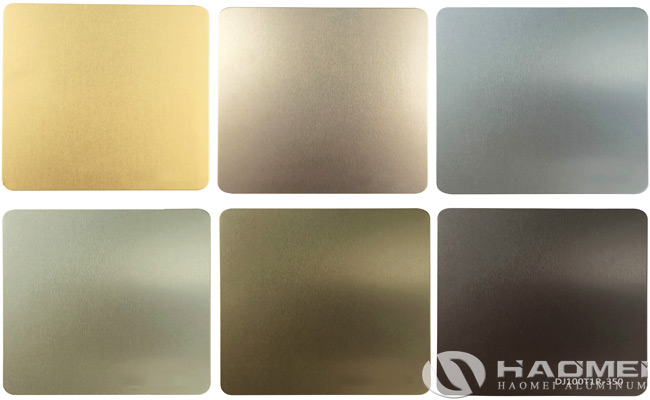

Through the anodizing and coloring process, colored anodized aluminum sheet can achieve a rich variety of colors, meeting the decorative and functional needs of various scenarios. The following are common color categories and characteristics:

- Basic Metallic Colors

– Silver/Natural

The oxide film is uncolored, revealing the aluminum’s natural metallic luster and creating a simple, modern look.

Applications: High-end electronic device casings (such as Apple products), architectural curtain walls, and industrial equipment.

– Champagne Gold/Bronze

Achieved through electrolytic or chemical coloring, it offers a warm, retro hue with a metallic finish.

Applications: Interior decoration, furniture accessories, and luxury goods packaging.

– Black/Dark Gray

Metal salts such as nickel and cobalt are deposited within the oxide film, creating a high-contrast, dark color. Applications: Electronic product frames, automotive interiors, and high-end kitchenware.

- Highly Saturated Colors

– Reds

Includes bright red, burgundy, and rose gold, achieved through organic dyes or electrolytic coloring.

Features: High visual impact, often used in brand logos and decorative artwork.

Applications: Mobile phone back panels, billboards, and fashion items.

– Blues

Includes sky blue, lake blue, and deep blue, offering fresh or calming tones.

Features: Blends a sense of technology with a natural feel, suitable for modern designs.

Applications: Appliance panels, architectural moldings, and sports equipment.

– Greens

Includes grass green, military green, and dark green, achieved through dyes or chemical coloring.

Features: Natural and eco-friendly style with excellent stain resistance.

Applications: Outdoor furniture, garden facilities, and medical equipment.

Core Features of Color Anodized Aluminum Sheet:

– Excellent Decorative Properties

Rich and uniform colors, with the ability to achieve metallic, matte, or gradient effects through process adjustment.

Various surface textures, including mirror, frosted, and brushed, meet diverse design needs.

– Strong Corrosion Resistance

The oxide film can reach a thickness of 5-30μm, effectively insulating the aluminum substrate from the external environment and significantly improving salt spray, acid, and alkali resistance.

– High Wear Resistance

The oxide film hardness can reach HV300-600, far exceeding that of ordinary aluminum, making it suitable for high-frequency contact scenarios.

– Environmentally Friendly and Pollution-Free

The process produces no harmful substances, complies with RoHS and other environmental standards, and is recyclable.

– Excellent Processability

It can be bent, stamped, and welded, maintaining the integrity of the oxide film and facilitating complex design.

Typical Applications of Color Anodized Aluminum Sheet:

– Architectural Decoration

Curtain walls, doors, windows, and ceilings: Leverage its weather resistance and aesthetics to enhance the modern feel of buildings.

Interior Decorative Panels: For applications such as elevator lobbies and shopping mall walls, personalized color schemes are available.

– Electronic Products

Mobile phone and laptop casings: Anodizing achieves a metallic finish combined with lightweight design.

Home Appliance Panels: For applications such as refrigerators and air conditioners, enhancing the product’s technological appeal and durability.

– Automotive Industry

Wheels and interior trim: Colored oxide films enhance vehicle recognition while meeting lightweight requirements. Daily Necessities

Lighting, Furniture, and Kitchenware: Leverage antibacterial and easy-clean properties to create high-end lifestyle products.

– Industrial Signage

Nameplates and Signs: Laser engraving or silk-screen printing on an oxide film creates long-lasting, weather-resistant markings.

Color anodized aluminum sheet, through innovative processing, perfectly combines aluminum’s lightweight, corrosion resistance, and decorative qualities, making it an ideal material for high-end manufacturing. Its environmentally friendly nature, customization capabilities, and wide applicability ensure its continued competitiveness in industries such as construction, electronics and automotive.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form