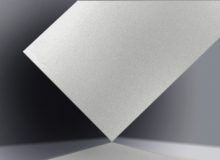

Anodized aluminum sheet

Anodized aluminum sheet is processed by anodizing based on aluminum sheet. Anodizing is an electrochemical process that forms a robust ceramic layer on the surface of aluminum sheet that is resistant to corrosion and UV. The anodized film is transparent, retains the appearance of the metal, and can be colored by electrolysis to provide a variety of color options.

| Alloy Series | Alloy Grade | Alloy Temper | Thickness | Width | Application |

| 5XXX | 5005 | O,H12,H14,H16,H18,H19,H116,H22,H24,H26,H32,H321,H34,H36,H38 | 0.1~3 | 900~2,400 | Decorative board, cabinet board, building curtain wall, etc. |

| 5052 | Chassis cabinet board, computer keyboard, LED backplane, IT board, etc. |

Anodized aluminium sheet plate is widely used in machinery parts, aircraft auto parts, precision instruments and radio equipment, architectural decoration, machine shell, lighting lamps, electronic consumer goods, handicrafts, household appliances, interior decoration, signs, furniture, car decoration and other industries.

There are also many other names of anodized aluminium sheets, such as:

anodized mirror aluminum sheet

mirror finish anodized aluminum sheet

anodized sheet aluminum

anodized aluminum sheet metal

anodized aluminum plate

The anodized aluminum sheet have lots of advantages:

- Good processability

The anodized aluminum sheet has strong decorative and moderate hardness, can be easily bent and formed, and can be continuously and rapidly stamped to facilitate direct processing into products, eliminating the need for complicated surface treatment and greatly shortening the production cycle and reduce product production costs.

- Good weather resistance

The anodized aluminum sheet with a standard thickness oxide film (3 μm) is not discolored and does not corrode in the room for a long time. The anodized alumina plate with a thick oxide film (10 μm to 25 μm) can be used for outdoor curtain walls and can be exposed to sunlight for a long time without discoloration.

- Strong metal sensation

The anodized aluminum sheet has high surface hardness, gem quality, good scratch resistance, no surface coating, retains the metallic color of the aluminum sheet, highlights the modern metal feel, and improves product quality and added value.

- High fire resistance

Anodized aluminum sheet belongs to pure metal products, no paint and any chemical substances on the surface, 600 degrees high temperature does not burn, no toxic gases are produced, and it meets the fire protection and environmental protection requirements.

- Strong stain resistance

No fingerprints, no stain marks, easy cleaning, no corrosion spots.

- Strong applicability

It is widely used in metal aluminum ceilings, curtain wall panels, aluminum-plastic panels, fireproof panels, honeycomb aluminum panels, aluminum single panels, electrical panels, cabinet panels, and furniture panels.

| Alloy Series | Alloy Grade | Alloy Temper | Thickness | Width | Application |

| 5XXX | 5005 | O,H12,H14,H16,H18,H19,H116,H22,H24,H26,H32,H321,H34,H36,H38 | 0.1~3 | 900~2,400 | Decorative board, cabinet board, building curtain wall, etc. |

| 5052 | Chassis cabinet board, computer keyboard, LED backplane, IT board, etc. |

Related Products

Mirror Finish Anodized Aluminum Sheet

Mirror finish aluminum sheet of Haomei aluminum are the best chice for you if you are looking for aluminum mirror sheet.Haomei Aluminum Sheet Plate

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form