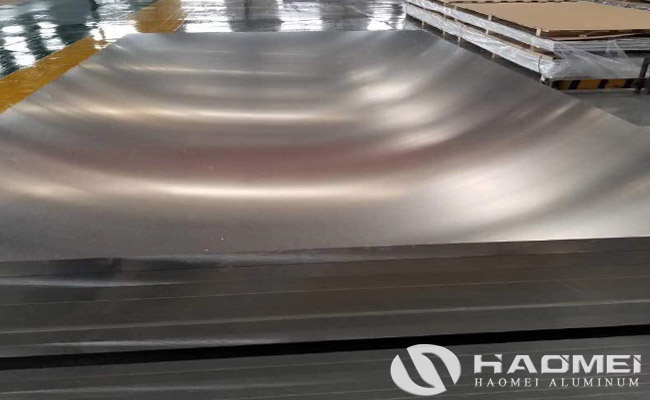

The thick china aluminum plate can be divided into ingot hot rolled thick plate and cast thick plate from the production process. Wherein the thickness of the cast thick plate can be basically unlimited (maximum thickness reaches 1.2 m), but the hot rolled thick plate has better mechanical properties after the rolled process, so the aerospace products generally use ingot hot rolled thick plates. However, the thickness of the hot-rolled aluminum plate cannot exceed 250 mm, otherwise the cast structure cannot be completely turned into hot-rolled structure.

The typical production process of ingot hot rolled thick aluminum plate is: raw material – casting – ingot milling – hot rolling – solution treatment – quenching – stretching – sawing. Since the temperature difference between the inside and outside of the plate during quenching is too large, when the thickness of the aluminum plate exceeds 6 mm, a large quenching residual stress is formed. The thicker the aluminum plate, the larger the internal quenching residual stress amplitude, and the greater the tensile force required for the stretching process. The tensile force required to stretch the aluminum plate up to 200 mm will reach 1 ten thousand tons, and this level of large tension stretching machine is not only high in technical indicators, and the investment is huge and difficult to introduce.

Most aluminum alloy thick plates are pre-stretched, and the production capacity of the stretching machine determines the production capacity of the china aluminum plate company. And only with higher advanced stretching machine, the different thickness requirements of aluminum plate buyers can be meet.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form