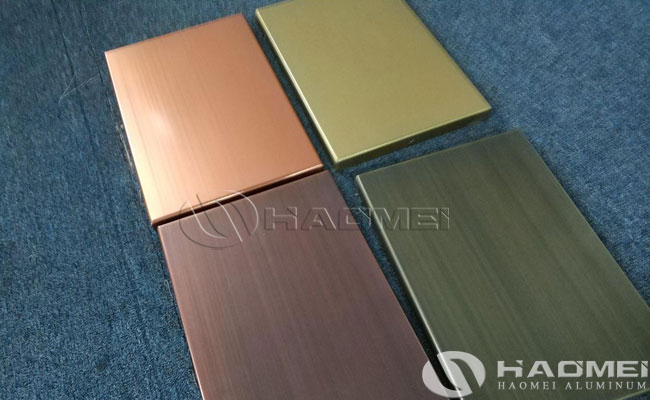

Bronze anodised aluminium is mostly adopt anodic oxidation electroplating electrolysis and other processes, the surface after oxidation treatment of aluminum sheet will have antique copper, red copper, purple copper and other dignified and elegant retro color. Anodised aluminum sheet is a great upgrade on the basis of the original aluminum oxide, which generates a thicker layer of aluminum oxide on the surface of the original aluminum sheet products, which not only can maintain the original metallic luster, but also can well prevent the product from oxidation.

Before selecting the oxidation process of bronze anodised aluminium, we should have an understanding of the material of aluminum or aluminum alloy. Because, the quality of the material, the different ingredients contained in the material will directly affect the quality of bronze aluminum sheet products after anodic oxidation. For example, if the surface of aluminum sheet has bubbles, scratches, peeling, roughness and other defects, all defects will still be revealed after anodizing. The alloy composition, on the surface appearance after anodizing, also has a direct impact. For example, aluminum alloy containing 1~2% manganese is brown-blue after oxidation, and with the increase of manganese content in aluminum, the surface color after oxidation is transformed from brown-blue to dark brown color. Aluminum alloy containing 0.6 to 1.5% silicon is gray after oxidation, and when it contains 3 to 6% silicon, it is white-gray color. Those containing zinc have a milky color, those containing chromium have a golden to gray uneven tone, and those containing nickel have a light yellow color. Generally speaking, only the aluminum containing magnesium and titanium containing more than 5% contains gold, after oxidation can get the colorless and transparent and bright, shiny and clean appearance.

After choosing good aluminum and aluminum alloy materials, naturally we have to consider the selection of a suitable anodic oxidation process. At present, the sulfuric acid oxidation method, oxalic acid oxidation method and chromic acid oxidation method are widely used in bronze anodised aluminium. The production process of bronze anodized aluminum sheet is not complicated, the cost is not high, the procurement is convenient, and it is widely used in construction, such as kitchenware and bathroom, furniture fireproof panel, wall fireproof and integrated ceiling production, all commonly use anodised bronze aluminium as the production raw material. It is the beauty and low cost of bronze anodized aluminium that makes it a popular material for building and decoration contractors. Its decorative and safety features also bring protection to the users of the products and greatly facilitate people’s lives.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form