Satin anodized aluminum sheet is a kind of aluminum product with special surface treatment. Its surface presents a satin-like texture, with high-end metal appearance and good decorativeness. This kind of aluminum sheet has enhanced its surface hardness, wear resistance, high temperature resistance and corrosion resistance through the anodizing process.

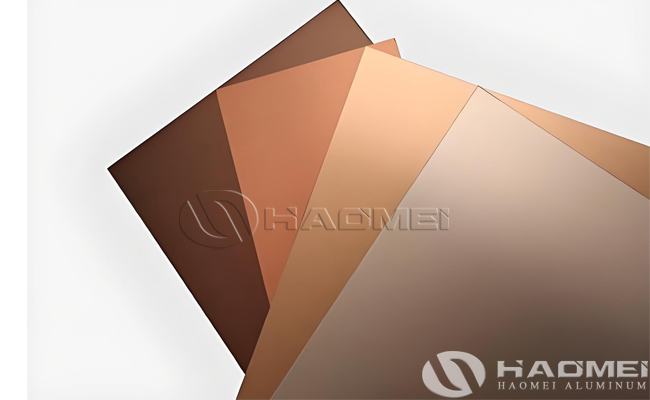

The core technology of satin anodized aluminum sheet lies in the anodizing process. By placing the aluminum sheet in an acid electrolyte (such as sulfuric acid, oxalic acid), direct current is applied with the aluminum sheet as the anode to form a dense aluminum oxide film on its surface. The satin effect is achieved by controlling the electrolyte concentration, current density, oxidation time and post-treatment process (such as sandblasting, chemical etching), and finally forming a delicate and uniform matte surface, which not only retains the metal texture but also gives a soft visual effect. Different combinations of these parameters can produce different satin effects. In addition to the standard aluminum color, satin effects in various colors such as champagne gold, gray, bronze, black, red, blue, etc. can also be customized.

Characteristics of satin anodized aluminum sheet including:

– Excellent corrosion resistance: The oxide film thickness can reach 10-30μm, which significantly improves the ability to resist acid, alkali and salt spray corrosion, and is suitable for outdoor and harsh environments.

– High hardness and wear resistance: The oxide film hardness of anodized aluminum sheet reaches HV300-500, close to gem grade, with excellent scratch resistance, and can maintain surface integrity after long-term use.

– Balance of aesthetics and functionality: Satin treatment reduces light reflectivity and avoids glare, while giving the product a high-grade matte texture, which has both practical and decorative value.

– Environmental protection and sustainability: The anodizing process has no heavy metal pollution, and the oxide film can be naturally degraded, meeting the green manufacturing standards.

Due to its excellent physical properties and high-end appearance texture, satin anodized aluminum sheets are widely used in various occasions that require high-quality decorative materials, such as:

- Architectural decoration field:

– Curtain wall and exterior wall: Satin treatment reduces light pollution and improves the texture of the building facade, suitable for high-end commercial complexes and cultural venues.

– Indoor partitions and ceilings: Matte surfaces reduce glare, create a comfortable space atmosphere, and meet fire and moisture resistance requirements.

- Electronic device housings:

– Smartphones and tablets: Satin anodised aluminum sheets have both anti-fingerprint and anti-scratch properties, improving product durability and grip feel.

– Industrial control equipment: Corrosion resistance ensures long-term stable operation of equipment in humid or chemical environments.

- Industrial product applications:

– Lighting fixtures: Matte surfaces optimize light diffuse reflection effects and improve lighting uniformity.

– Automotive parts: Used for interior trims or exterior trims to improve the texture and lightweight level of the entire vehicle.

The satin anodized aluminum sheet is not only beautiful and durable, but also provides a good user experience and visual effects in practical applications.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form