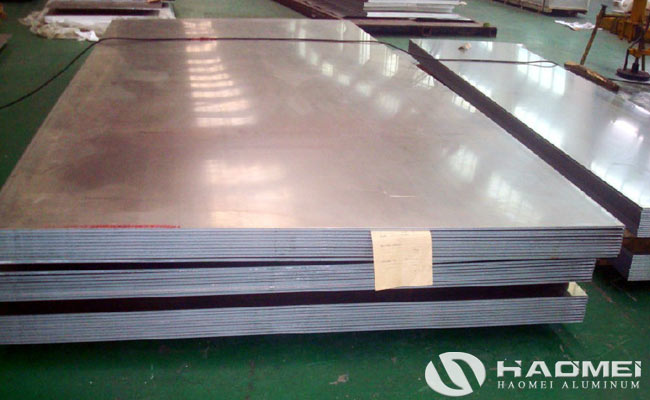

7075 t6 sheet, which means 7075 aluminum sheet after T6 strengthening treatment, has higher strength than general 7075 aluminium sheet. T6 means the strengthen treatment, after t6 treatment, the yield force and tension of aluminum 7075 sheet are greatly improved. At the same time, 7075 aluminum sheet alloy has good mechanical properties and anodizing properties. American ASTM standard The 7075 aluminum alloy is rated by the degree union as a B mechanical property, due to its ability to produce curled or brittle chips, and an excellent surface finish.

7075 t6 sheet aluminum alloy has a compact structure and strong corrosion resistance, which is better for aviation and marine plates application. 7075 aluminum alloy have normal corrosion resistance, good mechanical properties and anodic reaction. The fine grains provide better deep drilling performance and enhanced tool wear resistance. Main characteristics of 7075 T6 aluminum sheet: This is a commonly used super-hard aluminum, which is a high-strength alloy. It has medium plasticity in the annealed and just-quenched state, and can be heat-treated to strengthen. It is usually used in the artificial aging state of quenching. The strength obtained at this time is It is much higher than general hard aluminum, but has lower plasticity; the extruded semi-finished products and aluminum-clad plates with not too large cross-section have good corrosion resistance, the 7075 aluminum sheet alloy has the tendency of stress concentration, all transfer parts should be smooth transition, reduce eccentricity, etc. Spot welding is good, gas welding is poor, machinability after heat treatment is good, and machinability in annealed state is low.

The application of 7075 t6 sheet are make load-bearing components and high-load parts, such as girders, stringers, reinforcement frames, skins, ribs, joints, landing gear parts, etc. on aircraft. Usually used to replace 2A12 aluminum alloy.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form