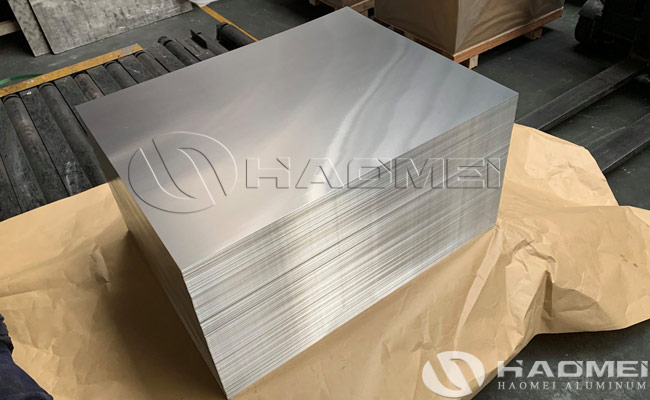

As a representative product of the industrial pure aluminum series, 1100 aluminum plate, with an aluminum content of no less than 99.0%, possesses excellent plasticity, corrosion resistance, and good thermal and electrical conductivity. It also boasts advantages such as low cost and ease of processing. These core attributes collectively determine its irreplaceable role in multiple industrial and civil fields. From practical engineering application experience, the application scenarios of 1100 aluminum sheet consistently revolve around its core material advantages, especially in fields with high requirements for material purity and formability, while strength requirements are relatively mild, demonstrating unique application value.

Heat exchange and refrigeration fields

The application of 1100 aluminum plate occupies an important position. Because the thermal conductivity of pure aluminum can reach 220 W/(m·K), far superior to ordinary alloy materials, 1100 aluminum sheet is often processed into heat sinks, evaporator cores, and condenser pipes for refrigeration equipment such as air conditioners and refrigerators. In actual production, 1100 aluminum sheets with a thickness of 0.2-1.0mm, after rolling and stamping, can achieve highly efficient heat conduction. Combined with their excellent resistance to water vapor corrosion, this effectively extends the service life of equipment. Application data from a large refrigeration equipment manufacturer shows that evaporators made with 1100 aluminum sheets have a 15%-20% higher heat exchange efficiency than traditional alloy materials, and show no significant corrosion even in long-term humid environments.

Packaging and container industry

Another core application area for 1100 aluminum plates, especially in the packaging of food, pharmaceutical, and chemical products. 1100 aluminum sheets are non-toxic, have a high surface finish, and are easy to print on. They can also be rolled into extremely thin aluminum foil substrates, which can then be laminated and formed into various packaging containers. For food packaging, 1100 aluminum sheets offer excellent barrier properties, effectively isolating oxygen, moisture, and light, extending the shelf life of food. In the chemical packaging field, their resistance to some acid and alkali media makes them suitable for containing less corrosive chemical raw materials. Currently, the thickness of 1100 aluminum foil used by mainstream food packaging companies in China is typically 0.012-0.02mm. After annealing, its elongation can reach over 35%, meeting the requirements of complex folding and forming processes.

Architectural decoration

1100 aluminum plate can be processed into ceiling and wall decorative panels and roofing waterproofing membranes. Its lightweight characteristics (density only 2.7g/cm³) reduce building loads, while also possessing excellent atmospheric corrosion resistance, allowing for long-term outdoor use without complex coating protection.

Electrical field

Utilizing its excellent conductivity, 1100 aluminum plate can be used to manufacture aluminum cores, busbars, and electrical housings for wires and cables. In low-voltage electrical equipment, busbars made from 1100 aluminum sheets can achieve a conductivity of over 60% IACS, and their good processing performance allows for complex circuit layouts through bending and welding.

With its golden balance of processability, corrosion resistance, and economy, 1100 aluminum plate has become a core basic material in many industrial sectors.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form