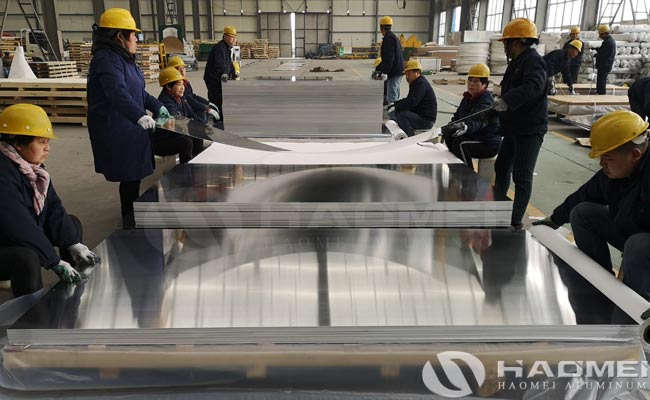

The precision aluminum plate produced by Haomei has the characteristics of good surface finish, high flatness of the surface and high precision of thickness tolerance. Especially thethickness tolerance of high-precision aluminum plate can be controlled within 0.05mm, and the flatness is better than other aluminum plate factory. The Haomei aluminum plate is widely used in the fields of electronic appliances, panels, inspection tools, fixtures and high-precision parts processing.

As an aluminum plate suppliers in China with over 20 years’ experience, to obtain a bright and straight aluminum plate, a flattening machine (or a calendered surface for calendering) can be used. The diameter of the work rolls of the leveler is large, and the surface must be polished, which is smooth and bright. When leveling the aluminum plate on the leveling machine, the pressure is usually 3~7 times, the reduction of each pass is very small, and the total reduction is not more than 2% of the thickness of the aluminium plate. Due to the low surface roughness of the work roll, the roll diameter is larger with less pressure, so that the rolled metal front is large, so that the board is flat and the surface is bright.

The roll type of the leveling machine is very important, especially when flattening the wide plate, the improper roll type is liable to cause wave and unevenness of the plate. The roller type of the work roll commonly used for the leveling machine can be seen as a flattening machine. In addition to the flat aluminum sheet, the aluminum plate sheet which needs to be cold-hardened after quenching can be cold-worked on the leveling machine. The cold work hardening of the plate is to level the large wave on the leveling machine after the plate is quenched, and the flatness is not more than 1%. After the natural aging condition is finished, the precision aluminum plate is cold hardened on the leveling machine. The total processing rate is 4% ~ 8%. In order to obtain a high-quality surface of the cold work hardened sheet, in the cold work hardening rolling, the transport guide and the roll should be wiped clean, and no lubricant is applied during the rolling.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form