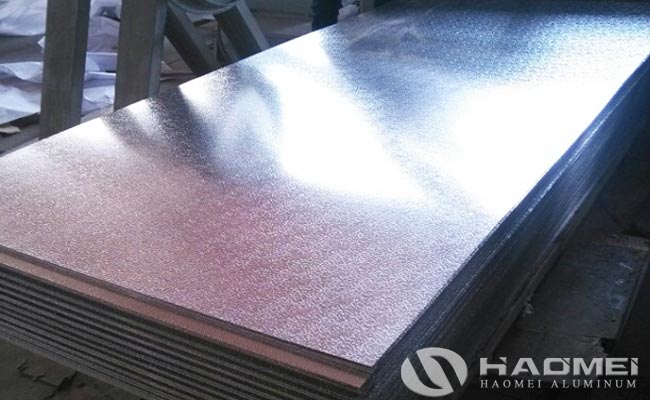

The embossed aluminum sheet used in the refrigerator evaporator is the orange peel aluminum sheet. The orange peel stucco aluminum sheet is subjected to pressure processing to form a pattern similar to orange peel pattern on the surface of the aluminum sheet coil. This series of products have good heat conduction and heat dissipation due to the particularity of the orange peel pattern. The main effect of the orange peel embossed aluminum sheet is to insulation and cold preservation, so it is usually used in refrigerators, chest freezer, air conditioners and other refrigeration equipment and pipe insulation.

The patterns of the orange peel aluminum sheet have classic orange peel and variation orange peel pattern. The uses can select suitable one according to the usage. The thickness of the orange peel stucco embossed aluminum sheet is between 0.2mm-1.0mm, the width is between 800-1226mm, the commonly used aluminum grade materials are: 1060, 1100, 3003, etc., the common seen thickness is 0.3mm, 0.45mm, 0.5mm, 0.6mm and 0.8mm. In the refrigeration industry, rust-proof 3003 orange peel stucco aluminum sheet coils are usually used. In the pipe insulation and packaging industry, pure 1060 orange peel embossed aluminum sheet coil are usually used. Color coated orange peel aluminum sheet coil is another kind of product with PE or PVDF spray / roller coating of various colors, the thickness is 0.024-4.0mm, the width is within 1700.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form