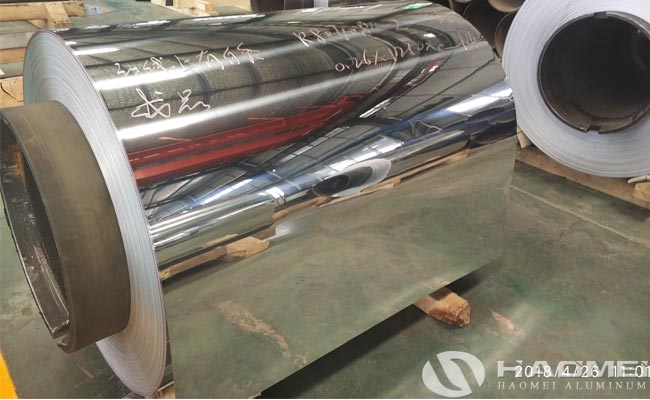

Mirror surface aluminum sheet is a specially treated aluminum sheet with a smooth and highly reflective surface, usually made by processes such as anodizing or polishing. The characteristics of mirror aluminum sheet include light weight, corrosion resistance, easy processing and excellent reflective performance, so it has been widely used in many fields.

Reflectivity is an indicator of the ability of a material surface to reflect light, usually expressed as a percentage. The reflectivity of mirror aluminum sheets is usually between 80% and 90%, depending on the surface treatment process and thickness of the aluminum sheet. High reflectivity gives mirror aluminum sheets a significant advantage in lighting and solar energy applications, helping to improve energy efficiency and light efficiency.

The reflectivity of mirror surface aluminum sheets varies due to their manufacturing process, surface treatment method and purity:

– Ordinary mirror aluminum sheet: Aluminum sheets that have been mechanically polished or chemically polished usually have a reflectivity of 85%~92% in the visible light range (400-700 nm). This type of product is often used in scenes where reflectivity is not demanding, such as architectural decoration and lamp reflectors.

– Anodized mirror aluminum sheet: If the surface is anodized (to form a protective layer), the reflectivity may drop slightly to 80%~88%, but the corrosion resistance and wear resistance will be significantly improved.

– High reflectivity aluminum mirror sheet: High-purity aluminum (such as 99.99% or more): Through precision processes such as electrolytic polishing or vacuum evaporation, the reflectivity can reach 92%~96%. Such materials are suitable for fields that require high reflectivity, such as optical instruments and laser reflectors.

Main uses of mirror surface aluminum sheet:

– Decorative materials:

Mirror aluminum sheets are often used in architecture and interior decoration, such as ceilings, walls, columns, etc., which can enhance the beauty and modernity of the space.

– Lighting equipment:

In lamp design, mirror aluminum sheets are often used in reflectors and lamp housings to improve the reflectivity and lighting effect of light.

– Solar reflectors:

Mirror aluminum sheets can be used for reflectors in solar collectors or photovoltaic systems to enhance the absorption and utilization efficiency of solar energy.

– Home appliances:

In the housing and internal structure of some home appliances (such as refrigerators, microwave ovens, etc.), mirror aluminum can enhance the appearance and durability of the product.

– Automobiles and transportation:

Mirror aluminum is sometimes used in the trim, interior and exterior reflectors of automobiles to enhance the appearance and improve safety.

– Displays and advertising:

In display stands, billboards and exhibitions, mirror aluminum can be used to attract attention and enhance visual effects.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form