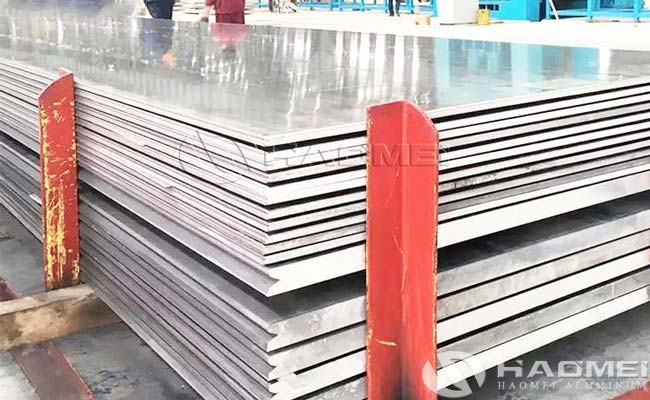

Hot roll sheet is also called as hot rolled sheet or hot rolling sheet, refer to aluminum sheet products processed by hot-rolling mills. Usually hot rolled aluminum sheets are made of aluminum sheet blanks with a thickness of 400-500 mm, which are processed by hot rolling mills for many times. Due to the greater pressure during processing, the internal structure is more uniform and the grain size is better. The microstructure of the hot roll aluminum sheet is more uniform and dense. After anodizing, the surface texture of the hot rolled aluminum sheet is consistent, without wave pattern and color difference.

In the process of hot roll sheet processing, the metallurgical structure, mechanical properties, surface quality of the hot rolled aluminum sheet and the geometric size and shape of the aluminum sheet must be reasonably controlled to meet the quality requirements of subsequent processing and final products. When hot rolling aluminum and aluminum alloys, the microstructure change is a very complicated process. First, the grains of the material are deformed under the action of a strong rolling force, and the cast grains are crushed and flattened, and the grains of the material are crushed and flattened along the rolling direction, elongation and simultaneous strain hardening occur, followed by dynamic recovery and possibly dynamic recrystallization.

Hot roll sheet products are generally divided into two categories, one is hot rolled thick aluminum plate, and the other is hot rolled aluminum sheet coil. Hot rolled thick aluminum plates refer to aluminum alloy plates with a thickness of not less than 6.0mm. The main varieties are hot-rolled plates (H112), annealed plates (O), quenched or quenched pre-stretched plates, etc. Hot rolled thick aluminum plates are usually used in hot rolling mills. It is produced by the block method, and its typical process is: ingot (homogenization) milling, edge milling, heating, hot rolling, shearing, interruption and straightening.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form