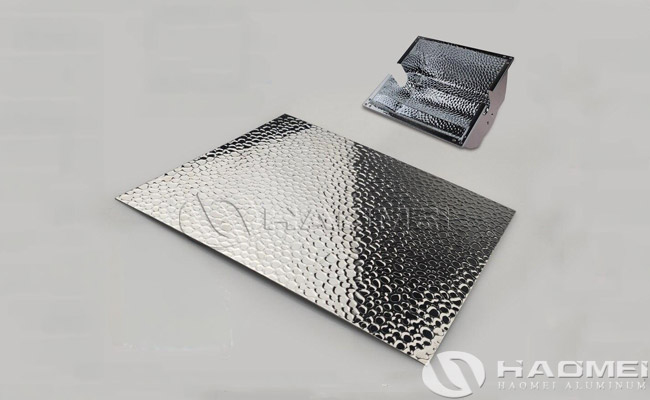

Hammertone reflective aluminum sheet is produced by embossing a hammered pattern onto the surface of aluminum sheet through a special process, followed by a mirror polish. This material combines the high reflectivity of mirrored aluminum sheeting with the diffuse reflectivity of hammered aluminum sheet, making it widely used in lighting, architectural decoration, solar energy, electronics, and other fields.

Common alloys of hammered reflective aluminum sheet include 1050, 1060, 1070, 1100, 3003, and 5052. Thickness generally ranges from 0.1mm to 7.0mm, with embossing depths of approximately 0.08mm to 0.25mm. Hammertone reflective aluminum sheet has a high reflectivity, typically between 83% and 95%. The specific value varies depending on factors such as the alloy material, surface treatment, and the depth and density of the hammered pattern. Hammered textures diffusely reflect light, dispersing concentrated light into a uniform spot and reducing glare. Suitable for applications requiring softer lighting (such as plant lights and interior decoration).

Surface Treatment of Hammertone Reflective Aluminum Sheet:

– Oxidation: Enhances corrosion resistance and forms a dense oxide film on the surface, extending service life.

– Embossed: Rolling or stamping creates textures such as hammered, bean-shaped, and orange peel patterns, increasing sheet strength (embossing can increase the thickness of the aluminum sheet by 0.1-0.25mm).

– Anti-Oxidation Polishing: Addresses the issue of mirror-like performance degradation and improves cleaning ease.

Physical Properties of Hammertone Reflective Aluminium Sheet:

Tensile Strength: 125N/mm²

Yield Strength: 105N/mm²

Elongation: ≥2%

Hardness: H18 (hard state)

Heat Resistance: Withstands high temperatures, suitable for use as solar collector reflective material.

Features of Hammertone Reflective Aluminum Sheet:

– Unique Appearance:

The combination of hammered texture and mirror-like gloss creates a unique visual effect on the aluminum sheet surface, creating a premium, stylish appearance that enhances the decorative and premium feel of the product.

– Corrosion Resistance:

Specially treated, it offers excellent corrosion resistance, resisting oxidation and corrosion, making it suitable for use in a variety of harsh environments.

– Wear Resistance:

The inherent hardness of aluminum alloy, combined with the mirror finish, makes the surface of hammer-textured reflective aluminum sheeting even more durable and resistant to scratches and abrasions.

– Easy to Clean:

The smooth surface resists dust and stains, making it easy to clean and maintain, maintaining its glossy appearance over time.

– Lightweight and High-Strength:

The lightweight and high-strength characteristics of aluminum alloy ensure that hammer textured reflective aluminum sheet maintains excellent strength and stability while remaining lightweight and easy to transport and install.

Applications of Hammertone Reflective Aluminum Sheet

– Lighting:

Widely used in reflectors for various lamps, such as fluorescent lamps and LED lamps. It can also be used as reflectors for solar products, such as solar water heaters and solar reflectors, effectively improving light reflection efficiency, enhancing lighting effects, and increasing the efficiency of solar energy utilization.

Growth Lamp Reflectors: The high reflectivity (over 95%) improves light efficiency, and the hammer-textured design reduces the risk of plant burns.

Indoor decorative lights: Bean-grain hammered aluminum sheets are used as lampshades to create a soft, gentle lighting environment.

LED lamp substrates: Mirrored aluminum sheets serve as heat dissipation substrates, reflecting light and improving lamp efficiency.

– Architectural decoration:

They can be used for interior and exterior decorative panels, such as wall coverings, ceilings, doors, and windows, adding a stylish and elegant ambiance to architectural spaces. They can also be used in furniture manufacturing, such as furniture surfaces, cabinet doors, and tabletops, enhancing the quality and aesthetics of furniture.

– Electronic and electrical appliances:

They are commonly used in electronic product casings, such as mobile phone and laptop cases, to enhance the product’s texture and elegance. They can also be used as decorative panels for electrical appliances, such as refrigerators and air conditioners.

– Signage:

Due to its high reflectivity and unique appearance, it is suitable for the production of various signs, remaining clearly visible in various lighting conditions and providing effective guidance and promotional purposes.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form