Chilled water pipe aluminium jacketing insulation is often an important part of the field of thermal insulation construction. The distinction between indoor and outdoor pipeline insulation is mainly due to different environments. Indoor pipelines include water supply pipelines, heating pipelines and factory manufacturing pipelines. They are not affected by the external environment. The choice of insulation method is relatively less restrictive. Outdoor pipes mainly refer to pipes used in factory production. Due to the influence of various types of weather in nature, outdoor pipe insulation needs more ways to choose.

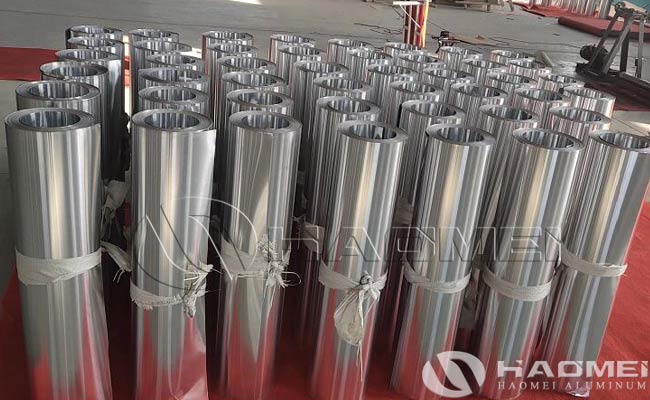

However, whether indoor and outdoor chilled water pipe are used as for insulation, the aluminum jacketing ASTM B209 can be selected. The aluminum jacketing sheet 1060 and 3003 H14 with thickness of 0.2-4mm is wrapped on the outer layer of the pipeline to form a protective layer. The aluminum jacketing not only reduces the exchange of the pipeline with the outside temperature, but also prevents the pipeline from being damp, rusted or corroded in different environments, thereby greatly extending the pipeline service life. Since then, both indoor and outdoor chilled water pipe aluminium jacketing insulation can be insulated with aluminum jacketing, this is an insulation technology that cannot disappoint you.

With the improvement of thermal insulation construction technology and thermal insulation materials, thermal insulation technology has been more and more widely used in the field of pipeline insulation. At present, the application scope of thermal insulation construction has been extended to coastal pipeline insulation projects, coastal urban factories and residential communities. The choice of thermal insulation technology must not only consider the thermal insulation effect, but also the adaptability of the insulation method to the local environment. The environment in coastal urban areas is humid, and the water in the sea water also carries salt substances, causing serious corrosion to chilled water pipelines. In this case, the emergence of chilled water pipe aluminium jacketing 3003 and 5005 just meets the needs of pipeline insulation in coastal suburbs, and has successfully become the main choice for pipeline insulation in coastal suburbs. The metal sheet used for insulation is aluminum sheet, which not only has low thermal conductivity, but also ensures particularly good insulation effect. It is difficult to be corroded and rusted, which can ensure a long service life and prevent rust and other conditions that affect the appearance. It is the main choice for coastal pipeline insulation.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form