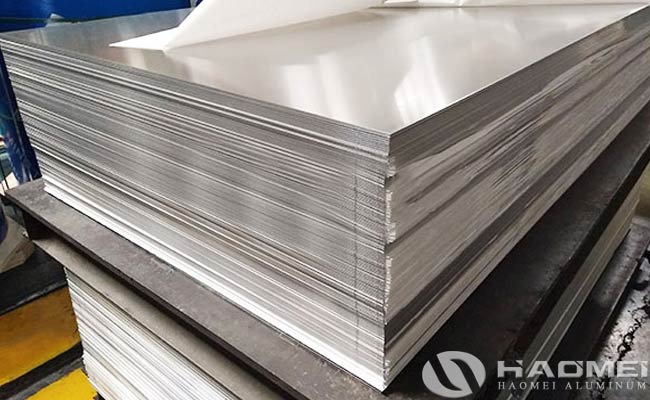

Annealed aluminum sheet refers to aluminum sheet that has been annealed, the grades including 1060, 3003, 5052, 6061 and so on. Annealing is a heat treatment process, by heating the aluminum sheet to a certain temperature and holding it for a certain period of time, and then slowly cooling it to change its internal organization and properties. The annealing treatment can eliminate the residual stresses inside the aluminum sheet, reduce the grain boundary energy, refine the grain, improve the plasticity and toughness of the material, and make it more uniform and stable.

Annealed aluminum sheet has the following features and advantages:

Improve plasticity:

Annealing treatment can eliminate the internal stress of aluminum sheet, reduce the hardness of the material, making it easier to carry out plastic deformation and processing.

Improved toughness:

Annealing improves the toughness of the aluminum sheet, giving it better resistance when subjected to impact or tension and reducing the risk of brittle fracture.

Improved weldability:

The annealing treatment can refine the grain size of the aluminum sheet, reducing the tendency of hot cracking during welding and improving the quality and reliability of the weld.

Improve corrosion resistance:

Annealing treatment can improve the surface quality of aluminum sheet, reduce surface defects and impurities, and improve its corrosion resistance.

Eliminate residual stress:

Annealing treatment can eliminate the residual stress produced in the processing or manufacturing process of aluminum sheet, preventing material deformation and cracking.

Annealed aluminum sheet is widely used in aviation, automotive, construction, electronics, packaging and other fields, especially in the need for high plasticity, toughness and corrosion resistance. Annealing treatment can improve the processing performance and service life of aluminum sheet, and improve product quality and reliability.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form