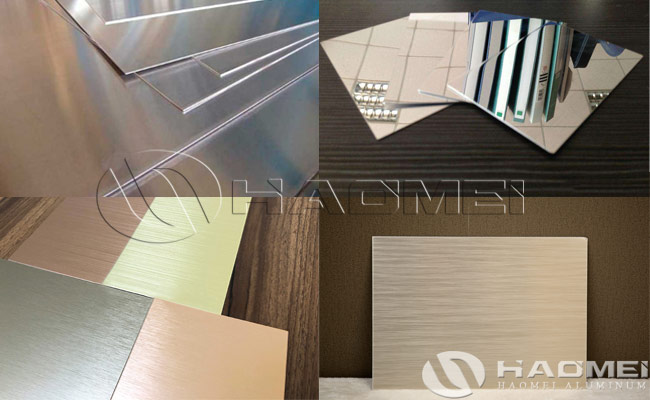

There are several aluminum sheet metal finishes in Haomei Aluminum to meet the requirement of different application. The finishes of aluminum sheet metal are mill finish, mirror finish, color finish, brushed finish and anodized finish. We have advanced and accurate processing equipment to ensure the quality of aluminum sheet metal in any progress. No matter hot rolling or cold rolling, the aluminum sheet metal product can meet the quality standard and have good reputation from our customer.

Mill finish aluminum sheet metal is the most common seen type of aluminum sheet metal finishes, the surface of mill finish aluminum sheet metal is clean and beautiful, and the price is low, it is widely used in packaging, decoration, construction and automobile industry. Mirror finish aluminum sheet metal is a kind of aluminum sheet product with super high reflectivity. It is manufactured through special processing technology. Therefore, its price is much higher than mill finish aluminum sheet metal. It is mainly used for the manufacture of high-end products.

Anodizing is an electrolytic oxidation process in which the surface of aluminum and aluminum alloys is usually transformed into an oxide film, which has protective, decorative and other functional properties. The anodization of aluminum starting from this definition includes only the part of the process of generating anodized film. In order to overcome the defects of aluminum alloy surface hardness, wear resistance and other aspects, expand the scope of application, and extend the service life, surface treatment technology has become an indispensable part of the use of aluminum sheet metal, and anodizing technology is currently the most widely used and most successful of.

The brushing process is a aluminum sheet metal finishes processing technique. Under the action of external force, the aluminum sheet metal is passed through a wire drawing roller or an abrasive belt to obtain the required texture. This process can improve the aesthetics of the aluminum sheet and conceal minor scratches on the surface. According to the different lines after drawing, it can be divided into: straight line drawing, medium and long line drawing, short line drawing, corrugation, and swirling. The brushed treatment can make the surface of the aluminum sheet metal obtain a non-mirror-like metallic luster, and the wire drawing treatment can also eliminate the subtle defects on the metal surface.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form