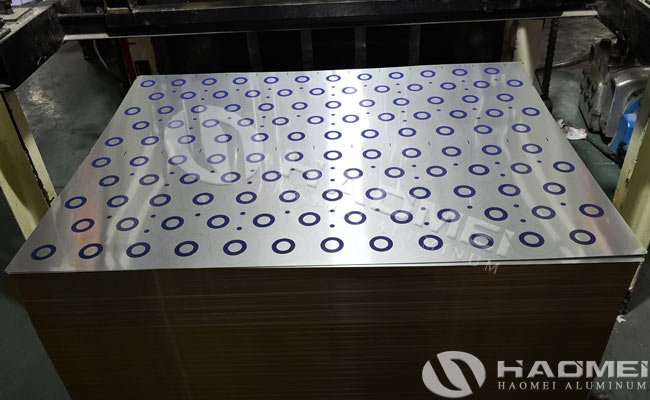

Aluminum sheet for metal cap generally use 8011 and 3105 aluminum alloys, the tempers are H14, H16, H24 and H26, the thickness is generally 0.15mm-0.3mm. Now the bottle cap materials is often made of aluminum. Aluminum sheet for bottle cap materials are increasingly used in people’s lives, replacing the original tinplate and stainless steel.

Some aluminum sheet metal caps are used in the cosmetics industry, and some are used in the pharmaceutical industry. 3105 and 8011 aluminum alloy can be generally directly stamped into caps, so they have better performance. Aluminum sheet for closure caps are also good choices for making liquor caps. The maximum punching depth can reach 60-80mm, and the oxidation effect is good. The proportion with tinplate can reach 1/10, the recycling rate is high, environmental protection and other advantages, so it is accepted by more manufacturers and customers .

Alloy 8011 aluminum closure sheet is mainly used for the production of medical bottle caps, with excellent moisture-proof performance, non-toxic and tasteless, safety and health; 3105 aluminum sheet for metal cap are mainly used for the bottle caps of cans, with extremely accurate thickness control, which can ensure a thickness tolerance of ± 0.005mm, it has good strength, corrosion resistance, good machinability and other characteristics, high surface finish to ensure the stability of later processing It is not easy to deform during transportation. The bottles and cans keep beautiful shape and fully meet the needs of customers.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form