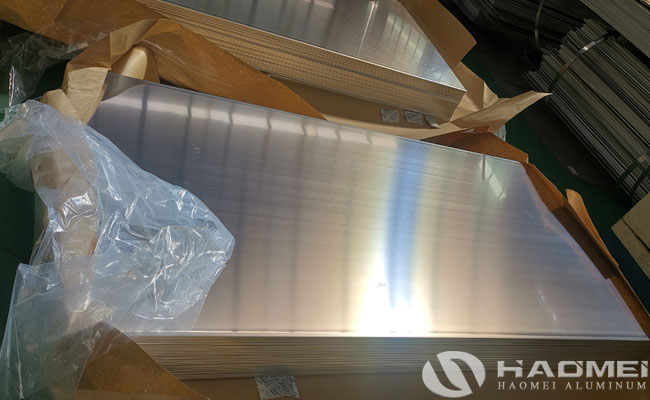

1100 H12 aluminum sheet, based on a high aluminum content of 99.00%, achieves a balance of performance through the H12 work hardening state, excelling in applications that balance formability and basic strength. From chemical equipment to electronic heat dissipation components, its stable technical characteristics make it a preferred material across various industries.

Composition control is the core of ensuring performance. Aluminum sheet 1100 h12 strictly adheres to GB/T 3880-2012 and US standard QQA 250/1, with an aluminum content consistently above 99.00%. Impurities are precisely controlled: silicon and iron combined do not exceed 0.95%, copper is controlled within the 0.05-0.20% range to optimize processing performance, and zinc and manganese contents are all below 0.10%. This high-purity composition not only endows 1100 aluminum sheet with excellent corrosion resistance, but also allows the corrosion rate of untreated samples to be controlled below 0.02 mm/year in neutral salt spray tests, with anodizing treatment achieving a doubling of this improvement.

The H12 temper processing technology determines its superior mechanical properties. Through moderate cold rolling, the sheet metal achieves a stable tensile strength of 110-136 MPa and a yield strength ≥50 MPa, representing a strength increase of over 40% compared to the O temper (annealed state), while retaining 3-5% elongation. This characteristic makes it less prone to cracking during cold working processes such as stamping and bending, making it particularly suitable for producing complex-shaped sheet metal parts. For example, 0.8mm thick 1100 aluminum sheet metal we supplied to a kitchenware company remained crack-free after 12 consecutive bends, meeting the requirements for deep drawing processes.

Thermal conductivity and weldability are key technical highlights. The thermal conductivity of 1100 H12 aluminum reaches 221 W/(m·K), approaching that of pure aluminum, demonstrating excellent performance in applications such as charging pile heat sinks and heat exchangers. In terms of welding, it is compatible with various processes including gas welding, arc welding, and spot welding. The joint strength after spot welding can reach 85% of the base material, and the welded area shows no significant corrosion tendency, which is crucial for the sealing of food and chemical storage equipment.

In terms of specifications and applications, we offer custom-made aluminum sheets with thicknesses ranging from 0.1-500mm and widths from 20-2650mm, with lengths up to 16000mm, to meet the needs of various scenarios. In practical applications, aluminum sheets are widely used in multiple fields, including but not limited to:

Food Industry:

Due to its excellent corrosion resistance and easy cleaning, 1100 H12 aluminum sheets are commonly used in food processing equipment and storage containers.

Chemical Industry:

In chemical reactors and storage tanks, the corrosion resistance of 1100 H12 aluminum sheets ensures the safety and durability of products.

Construction Industry:

As a building decoration material, 1100 H12 aluminum sheets are also widely used in exterior walls, roofs, and curtain wall systems.

Transportation Industry:

In the automotive and aerospace fields, 1100 H12 aluminum sheets, due to their lightweight and high strength, are often used in the manufacture of car bodies and fuselage structures.

With its excellent physical and mechanical properties, good processability, and wide range of applications, aluminum sheet 1100 h12 have become an ideal choice for many industrial sectors. Whether in the food, chemical, construction, or transportation industries, 1100 H12 aluminum sheets can provide reliable solutions.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form