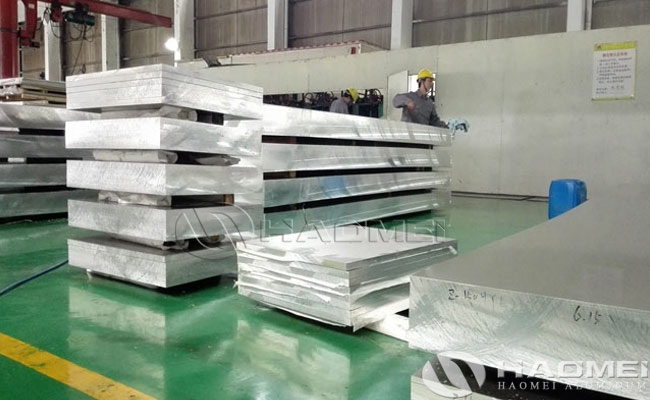

Haomei Al is an aluminum metal plate supplier and exporter in China with high quality, fast delivery, low price and perfect support. The aluminum plate produced by Haomei Aluminium are 1060, 3003, 5052, 5083, 5086, 6061 and 7075, which almost cover 1000 series aluminum to 8000 series. The processing of aluminum plate hot rolled in Haomei Aluminum is strict. What aspects are included in the heat treatment process of hot rolled aluminum plate? That are heating, heat preservation and cooling.

Detailed introduction of the three parts of aluminum metal plate heat treatment:

1, Heating.

Heating includes two parameters: heating speed and heating temperature of aluminum plate. Because aluminum plate alloy has good thermal conductivity and plasticity, it can be heated at a fast speed, which not only improves production efficiency, but also helps to improve product quality. Aluminum plate heating temperature should be strictly controlled, especially the heating temperature control during quenching and aging is more stringent, and the process regulations must be followed.

2, Heat preservation

Heat preservation refers to the residence time of the hot rolled aluminum alloy plate at the heating temperature. The residence time should ensure that the temperature of the metal surface and the center part is consistent. The structure of the aluminum alloy changes and the heat preservation time is related to many factors, such as product size, stacking method and tightness, heating method and the degree of metal deformation before heat treatment, etc. In production, the holding time is often determined based on experiments.

3, Cooling.

Cooling refers to the cooling of aluminum metal plate after heating and holding. The cooling rate of different heat treatments is different. For example, the quenching of 6061 aluminum plate requires a fast cooling rate, while the annealing of an aluminum alloy with phase change requires a slow cooling rate.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form