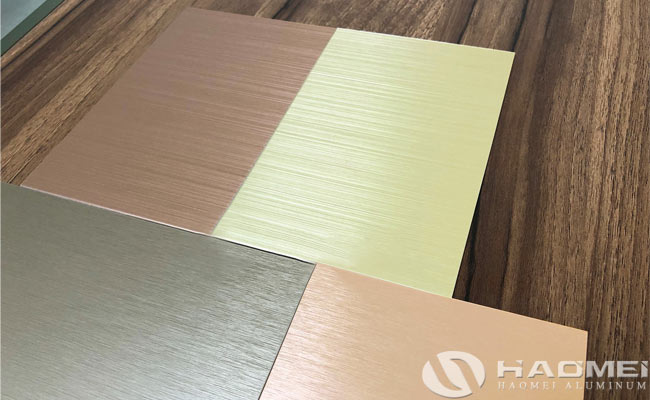

Aluminium sheet brush finish 1060 3003 is a kind of material that has beautiful appearance and is often used in decoration and manufacturing. By polishing the ordinary smooth aluminum plate, the surface of the aluminum plate has fine silk marks, and the surface emits the luster of the hair to make it look beautiful. The effect of the wire drawing can also make the aluminum plate have higher erosion resistance.

The aluminum alloy of brushed aluminium sheet are 1050, 1060, 1070, 1100-h14/24, 3003, 5052-h32, 6061, 6063 and 7075, the thickness of brushed aluminum sheet is 0.3-4.0 mm. The oxide film formed on the surface of the brushed aluminium sheet not only protects the brushed aluminum plate from erosion and wear, but also protects the safety of the product, because it has the metal hardness of the aluminum alloy, is not easily deformed, and has the decorative function. Moreover, the product made of brushed aluminum sheet is lighter than other metals.

Because the surface of the brush finish aluminium sheet is treated by special processing technology, the base material aluminum sheet also has a very high melting point. Therefore, in the application process of brushed aluminum sheet, even in the case of fire source, there will be no burning or combustion, or even can play a very good cut off fire source effect, so the application of brushed aluminium sheet material also has a good guarantee in terms of safety.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form