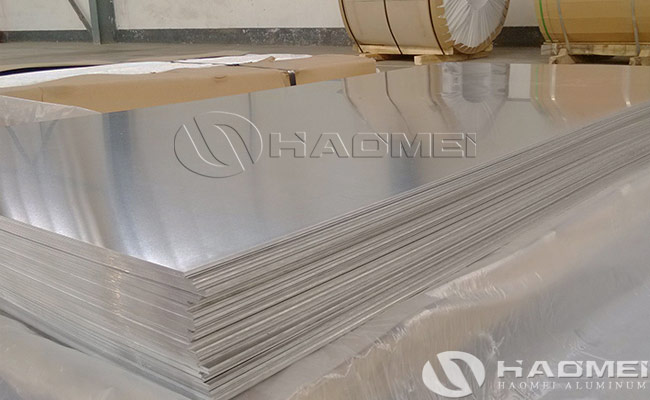

Aluminium 3003 alloy sheet is an AL-Mn alloy sheet, which is one of the most widely used types of rust-proof aluminum with good corrosion resistance and weldability for various applications. The production process of 3003 aluminium alloy sheet mainly includes the steps of raw material preparation, melting, casting, processing and surface treatment. The raw material preparation stage requires selecting high-purity aluminum as the main raw material and adding appropriate amounts of other alloying elements such as copper, manganese and so on. Then through the steps of melting, casting, processing and surface treatment, the required aluminium 3003 alloy sheet metal is finally obtained. The produced 3003 aluminum sheet surface quality is good, no oil spots, waves, scratches, roller marks, cut edges neat, no burrs.

Aluminium 3003 alloy sheet is a common rustproof aluminum sheet, hot rolling and casting process can be done. Haomei Aluminum produce 3003 aluminum sheet with the specification below:

National standard-GB3190-2008:3003

American Standard-ASTM-B209:3003

European Standard-EN-AW:3003/Al Mn1Cu

Alloy state: F, O, H12, H14, H16, H18, H22, H24, H26

Thickness: 0.2-150mm

Casting process 3003 aluminum sheet uses: color drawing board base, thermal insulation aluminum coil, curtain wall panel, small household appliances fins, filling material for air separation equipment, aluminum lunch box, honeycomb core, honeycomb panel.

Hot rolling process 3003 aluminum sheet uses: battery shell, water-cooled plate, deep-drawn material.

Here are some key features about aluminium 3003 alloy sheet:

Strength: it has high strength and hardness, suitable for applications requiring a certain degree of strength, but it is not strengthened by heat treatment, so cold working methods are usually used to improve its mechanical properties.

Plasticity: in the annealed state, 3003 alloy aluminum sheet has high plasticity; in the semi-cold hardening, its plasticity is still good; but in the cold hardening, the plasticity will be lower.

Corrosion resistance: the aluminum alloy plate has excellent rust characteristics, good corrosion resistance, good corrosion resistance to the atmosphere, fresh water, seawater, food, organic acids, gasoline, neutral inorganic salts in aqueous solutions, etc., for wet environments and chemically corrosive occasions.

Weldability: Its weldability is good, can be used in a variety of occasions requiring welding, easy to process into various shapes and sizes.

Cutting performance: despite its cutting performance is not good, but it is in other aspects such as forming and solubility and other aspects of good performance.

Aluminium 3003 alloy sheet metal is mainly used for processing parts and components that require good forming properties, high corrosion resistance and weldability, such as kitchenware, food and chemical product handling and storage devices, transportation of liquid products in tanks, tanks, to sheet processing of a variety of pressure vessels and pipelines, general artifacts, cooling fins, make-up panels, photocopier rollers, ship materials. In addition, it can also be used in various industries such as decoration, packaging, construction, transportation, electronics, aviation, aerospace, weapons and so on.

- 3003aluminum sheet is commonly used in the manufacture of automobile body panels, doors, roofs and other automobile parts.

- 3003 aluminum alloy sheet is suitable for manufacturing aviation devices, ship parts and other areas that require light weight and corrosion resistance.

- Alloy 3003 aluminum sheet can be used in the manufacture of building decorations, roof panels, wall panels and other decorative materials.

- 3003 aluminium sheet can also be used in the manufacture of kitchen utensils, home appliance shells and other products.

Overall, aluminium 3003 alloy sheet has many excellent characteristics and is suitable for application in many fields, which is a common and practical aluminum alloy material.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form