7000 series aluminum sheet belongs to the Al-Zn-Mg-Cu family of ultra-hard aluminum alloys and is one of the strongest wrought aluminum alloys currently used in the industry. Its core advantage lies in achieving a balance of light weight and high strength through precise alloying and heat treatment processes. 7000 series aluminum alloys primarily utilize zinc as the alloying element, resulting in high strength, low density, and excellent corrosion resistance. They are widely used in aerospace, transportation, sports equipment, and other fields. Common 7000 series aluminum alloys include 7075, 7050, 7475 and 7049.

- 1. Alloy Composition and Typical Grades

The 7000 series aluminium sheet is primarily composed of zinc (Zn) (typically 5%-7%), supplemented by magnesium (Mg) and copper (Cu) to form strengthening phases (such as MgZn₂), and contains trace amounts of chromium (Cr) or zirconium (Zr) to refine the grain size. Common grades include:

Contains 1.2-2.0% Cu and 5.1-6.1% Zn. It is the most classic high-strength grade, with a T6 tensile strength of up to 572 MPa. It is commonly used in the manufacture of aircraft structures and high-strength components.

– 7050:

Reduces the copper content to ≤2.0% and optimizes the magnesium-zinc ratio, offering 50% better stress corrosion resistance than 7075. It is commonly used in aircraft wing spars.

– 7475:

Through dual composite strengthening (grain boundary dispersed phase + subgrain structure), it maintains 90% toughness at temperatures as low as -60°C, making it a preferred choice for low-temperature aircraft components.

- 2. Mechanical Properties and Heat Treatment Mechanism

– Strength and Hardness:

In the T6 temper (solution treatment + artificial aging), 7075 aluminum sheet can achieve a hardness exceeding 150 HB, surpassing the tensile strength of most steels (such as AISI 4130). However, its elongation is only approximately 7-11%, requiring a balance between strength and ductility.

7050-T76, through two-stage aging (pre-aging + final aging), achieves a 20% improvement in fracture toughness while maintaining 500 MPa strength. Heat Treatment Process:

– Solution Treatment:

Quenching at 495-505°C forms a supersaturated solid solution.

– Aging Strengthening:

Single-stage aging (T6): Holding at 120-140°C for 24 hours produces high-density GP zones, rapidly increasing hardness.

Dual-stage aging (T73): Low-temperature pre-aging forms GP zones, followed by high-temperature aging to generate η phase (MgZn₂), significantly reducing the risk of stress corrosion cracking.

Non-isothermal aging: Dynamic temperature control (e.g., a heating rate of 1-5°C/min) shortens the cycle while optimizing the distribution of precipitated phases, resulting in overall performance superior to traditional isothermal treatment.

- 3. Corrosion Resistance and Surface Treatment

– Inherent Characteristics:

T6 temper exhibits poor corrosion resistance and is highly susceptible to intergranular corrosion and stress corrosion, requiring reliance on surface protection.

T73 temper, by adjusting aging parameters, increases the spacing between precipitated phases at grain boundaries, improving stress corrosion resistance by more than three times.

– Protective Technologies:

Aluminum Cladding: A pure aluminum layer (such as 7072) is applied to the sheet surface, protecting the substrate through sacrificial anodes. This process is commonly used for 7475 aluminum sheet for aviation applications.

Anodizing: Produces an Al₂O₃ oxide film with a thickness of up to 10-25μm, providing both decorative and protective properties.

Painting or Electrophoresis: Provides an additional barrier in challenging environments, such as acrylic coatings commonly used on automotive parts.

- 4. Processing Characteristics and Key Process Points

– Forming and Cutting:

Cold Working: The annealed state (O state) exhibits good plasticity and can be formed by rolling or extrusion, but has a high work hardening rate and requires intermediate annealing.

Hot Working: The optimum temperature is 400-450°C. Direct quenching after hot extrusion can achieve “in-line heat treatment.”

Cutting Performance: High hardness (HB 150+) requires carbide tools (such as cobalt-containing high-speed steel). Recommended cutting speeds are 80-120 m/min and feeds are 0.1-0.3 mm/r.

– Welding Challenges:

Conventional arc welding can easily soften the heat-affected zone, resulting in a strength loss of up to 30-50%. Friction stir welding (FSW) or laser welding is required.

ER718 (containing 5.2-6.2% Zn) is recommended as a filler material, which can restore weld strength to over 85% of the base material.

- 5. Applications and Typical Cases

– Aerospace:

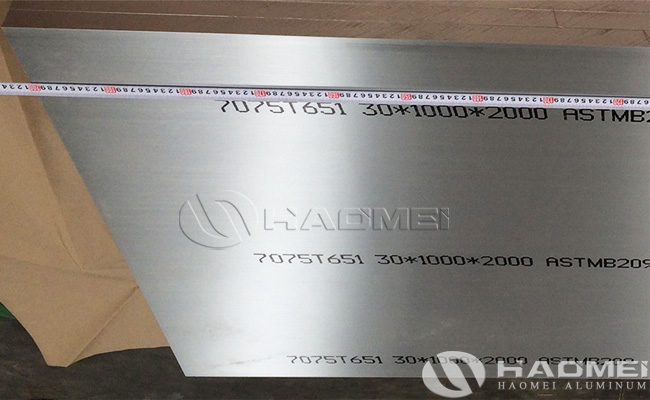

Main Bearing Structures: 7075-T651 is used in the Boeing 787 wing skin, withstanding 560 MPa tensile stress. 7050-T76 is used in the Airbus A350 fuselage reinforcement frame, reducing weight by 15%.

Landing Gear Systems: 7178-T7651 bolts have a tensile strength of 605 MPa, replacing titanium alloys and reducing costs by 40%.

– Automotive Industry:

Lightweight Components: The Tesla Model Y battery pack bracket uses 7003 alloy, which improves collision energy absorption by 20% while reducing weight by 25kg.

High-Performance Parts: The Porsche 911 GT3 RS’s suspension arm uses 7075-T6, which boasts a tensile strength three times higher than traditional steel.

– High-End Manufacturing:

Precision Molds: 7075 T6 is used in CNC molds for mobile phone midframes, achieving a hardness of HB 160+ for long-term wear resistance.

Robotic Joints: The rotation axis of the Fanuc M-20iA robotic arm uses 7050-T7451, maintaining an accuracy of ±0.02mm under high loads.

- 6. Standards and Quality Control

7000 series aluminum sheet adheres to strict international standards, including:

– ASTM B209:

American Society for Testing and Materials standard, specifying the mechanical properties of sheet thickness ≤ 150mm;

– EN 573-3:

European standard, with higher requirements for chemical composition and surface quality (e.g., Fe+Si ≤ 0.45%).

- 7. Cost and Market Trends

7000 series aluminum sheet is significantly more expensive than 6000 series aluminum sheet, primarily due to:

The higher cost of alloying elements (especially zinc and copper);

The complex heat treatment process, with energy consumption accounting for over 30% of production costs;

Aerospace-grade products require 100% non-destructive testing, increasing quality inspection costs by 15-20%.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form