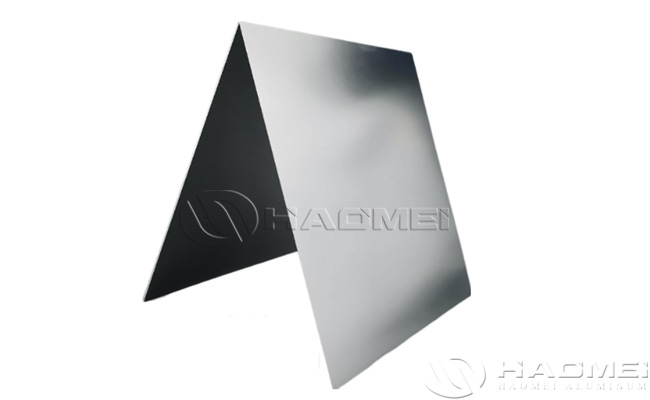

Grey anodized aluminum sheet is a high-performance decorative and functional sheet made by surface treatment of high-quality aluminum alloy sheet (common grades such as 1050, 1060, 1100, 3003, 5005, 5052, 6061, 6063, etc.) through anodizing process. A dense and hard aluminum oxide (Al₂O₃) ceramic layer is formed on its surface, and a uniform, stable and textured gray tone is presented through special electrolytic coloring or overall coloring process. This process not only gives the aluminum sheet excellent surface properties, but also retains the modern and high-end feel of the metal.

Typical technical parameters of grey anodized aluminum sheet:

– Substrate thickness: 1.0mm, 1.5mm, 2.0mm, 2.5mm, 3.0mm, 4.0mm, etc.

– Oxide film thickness: AA20 (≥20μm), AA25 (≥25μm), etc. (in accordance with GB/T 5237.2, QUALICOAT, GSB, etc.)

Surface treatment: matte, glossy

– Color: light gray, medium gray, dark gray, silver gray, gun gray, etc. (RAL or Pantone color selection or customization is available)

– Hardness: ≥ HV 300

– Salt spray corrosion resistance: ≥ 1000 hours (CASS test or neutral salt spray test, no corrosion points)

– Weather resistance: Pass QUV or xenon lamp aging test (such as 4000 hours ΔE<3)

– Abrasion resistance: ≥ 500 times (sand falling test or Taber abrasion test)

– Sealing quality: The dye spot method or acid immersion method is qualified

Core process of grey anodized aluminum sheet manufacturing is anodizing, it including:

– Electrolytic oxidation:

The aluminum sheet is used as an anode in an acidic electrolyte, and a direct current is passed. An electrochemical reaction occurs on the aluminum surface to form a porous aluminum oxide film.

– Coloring:

Gray is mainly achieved in two ways

Electrolytic coloring: Metal salts (such as tin salts, nickel salts, etc.) are deposited in the porous oxide film. By controlling the deposition time and current, the depth of gray (such as light grey, medium grey, dark grey, gun grey, etc.) can be accurately controlled.

Overall coloring: Direct oxidation in an electrolyte with a specific composition (such as an organic acid mixture) to generate a colored oxide film. Gray can also be obtained through this process.

– Sealing:

After coloring, the porous oxide film is subjected to high-temperature hydration or cold sealing treatment to seal the micropores, greatly improving the corrosion resistance, wear resistance and pollution resistance of the film.

Core advantages and characteristics of grey anodized aluminum sheet are:

– Excellent weather resistance and durability:

The chemical properties of the oxide film layer are extremely stable, non-fading, non-discoloring, non-powdering, and can resist long-term erosion from harsh environments such as ultraviolet rays, acid rain, and salt spray. The service life can reach more than 20-30 years.

The color is stable and lasting, and it will last forever.

– Excellent surface hardness and wear resistance:

The anodized film has high hardness (up to HV 300 or more, much higher than ordinary aluminum), is scratch-resistant and wear-resistant, and the surface is not easy to scratch, which is suitable for high-traffic areas.

– Rich texture and aesthetics:

A variety of color options are available, from light gray to dark gray, matte to glossy, etc., to meet different design needs.

The surface presents a delicate metallic matte or silky texture, with uniform color, elegance, stability, and modernity, with a unique sense of high-end and technology.

– Excellent corrosion resistance:

The oxide film is the natural barrier of the aluminum sheet itself. Combined with the sealing treatment, it has strong corrosion resistance, especially suitable for corrosive environments such as coastal areas and industrial areas.

– Good self-cleaning and easy maintenance:

The surface is dense and smooth, and it is not easy to absorb dust and stains.

Clean and maintain it simply and conveniently, generally it can be washed with rainwater, or wiped with a neutral detergent.

– Environmentally friendly and non-toxic

The main component is alumina, which does not contain VOC (volatile organic compounds), is non-toxic and harmless, and meets the requirements of green buildings and environmental protection.

It can be 100% recycled and reused, and is sustainable.

– High heat resistance and fire resistance:

Alumina has a high melting point (about 2050°C), and the aluminum substrate itself is non-flammable (A-grade fireproof material), and has good fire resistance.

– Good processability and adaptability:

It retains the excellent flexibility, plasticity and strength-to-weight ratio of aluminum sheets, and is easy to cut, stamp, bend, roll arc and other processing, and adapts to complex shapes.

It can be compounded with various backboard materials (such as honeycomb aluminum core, PE core, fireproof board, etc.) to make aluminum honeycomb panels, aluminum-plastic panels, etc.

Application of grey anodized aluminum sheet including:

– Architectural decoration:

Used for architectural decoration such as exterior walls, interior walls, curtain walls, etc., to enhance the beauty and durability of the building.

– Furniture:

In modern furniture, it is often used for desktops, chairs, cabinets, etc. to add a sense of fashion.

– Electronic products:

Used in the shells of consumer electronic products such as mobile phones and computers to provide protection and beauty.

– Transportation:

Used as structural materials and decorative materials in transportation vehicles such as cars and ships.

– Industrial equipment:

Used to manufacture various mechanical equipment and tools, and is widely used due to its excellent physical properties and durability.

Why choose gray anodized aluminum sheet?

– Lasting aesthetic value: Gray is a timeless classic color, and the metallic texture gives it a modern, low-key and luxurious temperament, and the color is stable and unfading.

– Extremely long service life: significantly reduce maintenance and replacement costs, and the cost of the entire life cycle is better.

– Excellent physical properties: meet the requirements of harsh environments for weather resistance, wear resistance, and corrosion resistance.

– Green and environmental protection: in line with the architectural concept of sustainable development.

– Design flexibility: Rich grayscale and texture options to adapt to a variety of design styles (modern simplicity, industrial style, technology, etc.).

Grey anodized aluminum sheet has become a popular surface treatment material in modern high-end architecture, industry and home fields due to its unparalleled durability, unique metal texture, rich gray options, excellent physical and chemical properties and environmental protection characteristics. It is an ideal choice for pursuing long-term value, aesthetic quality and reliable performance.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form