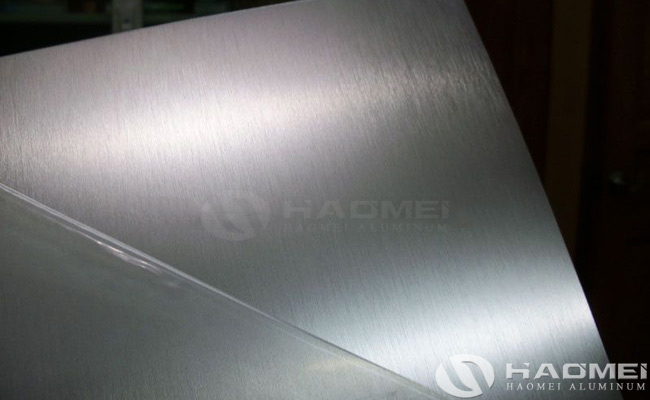

Brushed aluminum sheets achieve a uniform linear texture on their surface through precision mechanical friction, combining the authentic feel of metal with excellent physical and chemical properties, making them a preferred material for high-end manufacturing and architectural decoration. Based on over ten years of export processing experience at Haomei Aluminum, the core of high-quality brushed aluminum sheets lies in the scientific selection of the alloy substrate—different alloy compositions directly determine the product’s strength, corrosion resistance, processability, and applicable scenarios. In our production, we have found that specifically matching the alloy to the application scenario can extend the product’s lifespan by more than 30%, which is also the core basis for providing customized solutions to global customers.

Combining international market demands, Haomei Aluminum’s mainstream brushed aluminum sheet specifications cover: thickness 0.3-3.0mm, width 1-2m, and length can be cut to order (standard 2.5m/3m). The brushing process can be customized with various textures such as straight lines, short lines, and random lines. The abrasive belt mesh is adjustable from 80-600 grit, with 180-400 grit being a common and preferred choice for the construction and electronics industries. Key quality indicators strictly adhere to ASTM and EN standards, with texture uniformity and color difference ΔE ≤ 1.5, and salt spray resistance ≥ 1000 hours, ensuring export products are suitable for environmental requirements in different regions.

Detailed explanation of mainstream alloy series of brushed aluminum sheets:

- 1000Series Pure Aluminum (1050/1060/1100):

Aluminum content ≥ 99%, with a delicate and uniform brushed finish and affordable cost. However, its strength is relatively low, making it suitable for decorative applications where high mechanical performance requirements are not necessary. We recommend it as a priority choice for customers exporting to the Southeast Asian home decoration market due to its significant cost-effectiveness advantage.

- 3000Series Aluminum-Manganese Alloy (3003):

With a core alloying element manganese content of 1.0-1.5%, it boasts excellent rust resistance, making it the first choice for humid environments. Our practical verification shows that its salt spray resistance is superior to the 1000 series, and it is widely used in industrial fields such as air conditioning and cold storage. Orders from refrigeration equipment manufacturers in Europe and America account for 40% of its total exports.

- 5000 Series Aluminum-Magnesium Alloys (5052/5083):

With a magnesium content of 3-5%, these alloys offer a balance of strength and ductility, and excellent wire drawing properties, making them a mainstream choice in high-end applications. 5052 aluminum is suitable for electronic device housings, while 5083 aluminum can be used in high-strength applications such as marine and rail transportation, and has been validated in harsh environments in the Middle East and Northern Europe.

- 6-Series Aluminum-Magnesium-Silicon Alloys (6061/6063):

Combining the advantages of magnesium and silicon, these aluminum alloys can be heat-treated for strengthening and offer both corrosion resistance and machinability. They are suitable for complex structural parts requiring bending and stamping, making them a preferred material for interior components in new energy vehicles.

Based on alloy properties and global case studies, application scenarios can be precisely matched:

1000 series/3000 series brushed aluminum sheets are suitable for decorative applications such as building ceilings and appliance panels;

5000 series brushed aluminum sheets are widely used in high-end electronic device housings and shipboards;

6000 series brushed aluminum sheets focus on automotive parts and precision mechanical components. Haomei Aluminum offers customized solutions for different export destinations.

For example, 5000 series brushed aluminum sheet alloys are used to enhance salt resistance for customers in coastal areas, while 6000 series brushed aluminum sheet alloys are used to ensure precision machining for high-end electronics customers.

From raw material selection to finished product testing, Haomei Aluminum always focuses on alloy properties, using full-process quality control such as spectrometer composition analysis and 3D profilometry texture verification to ensure that every batch of brushed aluminum sheets meets international standards. For specific application scenarios, please contact us for customized alloy solutions.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form