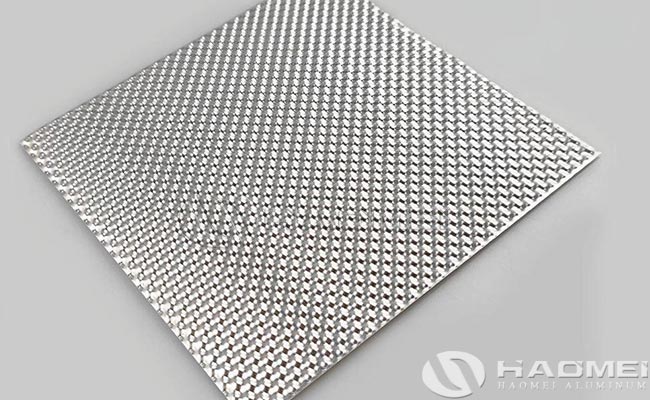

Hemispherical embossed aluminum sheet, also known as semi-circular spherical or pearl-shaped embossed aluminum sheet, features a hemispherical raised pattern on its surface. This type of aluminum sheet is widely used in construction, decoration, transportation, and other fields, and offers a variety of excellent properties.

Pattern Features

The surface features a pattern of small spheres arranged like pearls. The pattern is formed through a embossing process with a density of 156 ± 17 spheres and a embossing height of 2 ± 0.05 mm.

Specifications

Material: Commonly used are pure aluminum grades such as 1050 and 1060, often in an O state (soft state), making them easier to stamp and form.

Thickness: Generally ranges from 0.2mm to 1.0mm, although some manufacturers can process thicknesses of 0.15mm to 2.0mm.

Width: Typically no more than 1000mm, though some embossed aluminum sheet manufacturers can produce wider widths of 1350mm or 1500mm. Length: Available in sheet or coil form, with specific lengths customizable upon request.

Performance Advantages

– Excellent Heat Dissipation:

The hemispherical pattern increases surface area, significantly improving heat dissipation compared to ordinary aluminum flat sheets and other embossed aluminum sheets, making it suitable for applications requiring heat dissipation.

– High Strength:

The unique pattern structure provides greater strength than other embossed aluminum sheets, allowing it to withstand external forces and stamping processes.

– Corrosion Resistance:

Aluminum inherently possesses excellent corrosion resistance, and hemispherical embossed aluminum sheet inherits this property, making it suitable for use in a variety of environments.

– Lightweight:

The density of pure aluminum is only one-third that of steel. At the same weight and thickness, it offers significantly more usable surface area than steel, making it easier to transport and install.

– Unique Aesthetics:

The hemispherical pattern lends it a unique and decorative appearance, making it suitable for applications requiring aesthetic appeal.

Processing Technology

The process of hemispherical embossed aluminum sheet typically involves unrolling the mother roll, embossing, inspection, winding, and packaging. Embossing machines are forged from high-strength steel, with rollers typically around 500mm in diameter, ensuring full, uniform embossed patterns.

Applications of hemispherical pattern embossed aluminum sheet:

– Automotive Industry:

This series of patterned products is commonly used in automotive engine compartments and exhaust manifold shields. They can be used to produce stamped engine heat shields, heat shield parts, engine heat shields, radiators, and exhaust manifold heat shield components. They are widely used by numerous automakers, including GAC, Volkswagen, and Ford.

– Insulation Engineering:

This type of product can be used in insulation projects. The embossed surface scatters sunlight, reducing light pollution and providing a certain degree of insulation.

– Packaging:

Due to its aesthetically pleasing appearance and high strength, it is used in outer packaging, such as packaging boxes.

– Other Industries:

It can also be used for heat dissipation in petroleum and chemical equipment, as well as decorative and structural components in refrigerators, air conditioners, and vehicle interiors in furniture manufacturing. It can also be used for applications such as lampshade reflection.

Hemispherical embossed aluminum sheet, due to its lightweight, functional, and cost-effective advantages, has become a key material in the automotive and construction industries.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form